¶ 500W Cold Air Spindle Motor Kit

The 500W Cold Air Spindle Motor Kit is an upgrade kit designed specifically for the TT450 engraving machine, aimed at enhancing the spindle performance and functionality. Here’s the main introduction of this kit:

500W Cold Air Spindle Motor: This kit features a 500W cold air spindle motor. Compared to traditional spindles, this cold air spindle motor offers higher power and efficiency, providing stronger engraving capabilities and more stable operational performance.

Increased Speed to 12,000 RPM: The kit boosts the original TT450 engraving machine’s spindle speed from 7,000 RPM to 12,000 RPM. This increased speed enables the engraving machine to complete machining tasks more quickly, enhancing production efficiency.

Speed-Controllable Control Box: The accompanying control box features speed-adjustable functionality, allowing users to flexibly adjust the spindle speed according to specific machining needs. This controllable speed capability enables users to select suitable speeds based on different materials and machining requirements, achieving higher-quality machining results.

Cold Air Cooling Design: The cold air spindle motor adopts a cold air cooling design, effectively reducing spindle temperature and improving equipment stability and reliability. This design also reduces the impact of heat generated during the machining process on the workpiece, ensuring machining quality.

Easy Installation and Operation: The kit provides detailed installation instructions and operation guides, enabling users to easily complete installation and debugging work. Additionally, the control box is intuitively operated, making it easy for users to operate and adjust.

The 500W Cold Air Spindle Motor Kit offers an upgraded spindle solution for the TT450 engraving machine. By increasing speed and introducing controllable speed functionality, it enhances the machine’s machining capabilities and flexibility, suitable for various types of machining needs.

¶ Kit Details

¶ CNC Fourth Axis

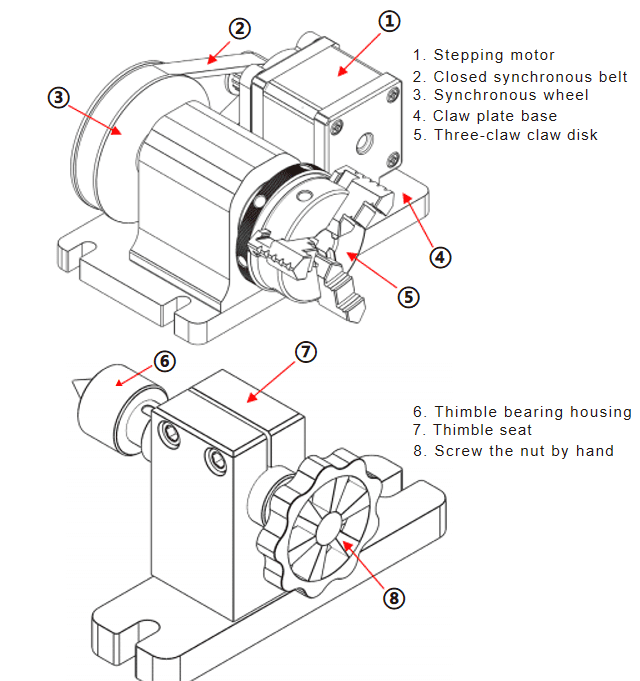

The CNC Fourth Axis Kit is designed for use with the TT450 engraving machine, enabling engraving or machining of rotating materials. Here are the main components of the kit and their functional descriptions:

Chuck Fixture: The chuck fixture is one of the main components of the fourth axis kit, used to clamp rotating materials. This type of chuck typically features adjustable clamping force to accommodate different diameters and lengths of rotating workpieces. Made of high-strength metal, the chuck fixture ensures secure clamping and durability.

Centering Pin: The centering pin is an auxiliary tool used to secure rotating materials on the chuck fixture. It is used to press against the center of the material, fixing the rotating material in place with pressure to ensure stability and accuracy during machining.

Rotary Machining Function: By installing the fourth axis kit, the TT450 engraving machine can achieve machining of rotating materials, such as engraving, cutting, and hollowing. This machining method allows the engraving machine to handle more complex geometric shapes, such as three-dimensional sculptures and rotating cylinders, expanding the application scope of machining.

Application Fields: The fourth axis kit is widely used in woodworking, engraving, mold manufacturing, and other fields. Through the rotary machining function, users can achieve more diversified and creative machining effects, improving work efficiency and product quality.

Easy Installation and Operation: The fourth axis kit provides detailed installation instructions and operation guides, enabling users to easily complete installation and debugging work. The operation is simple and intuitive, suitable for users of different skill levels.

The CNC Fourth Axis Kit provides the TT450 engraving machine with the capability to machine rotating materials. Through components such as the chuck fixture and centering pin, it achieves clamping and fixing of rotating workpieces, expanding the application scope of machining and enhancing flexibility and efficiency in machining operations.

The CNC fourth axis sleeve is currently only compatible with worktables like TTC450 and TTC450Pro that are fixed by threaded holes. In theory, TTC6050 can also be used, but it requires manual alignment, which poses certain installation difficulties

¶ Kit Details

- Brief Introduction

- Assembly video

- User Guide

- Common Fault Information

- Regular Maintenance And Upkeep

¶ Edge Trimming Kit

The edge trimming machine spindle motor kit is another upgrade kit for CNC, with a more powerful rotation compared to the 500W cold wind spindle: Here is an introduction to this spindle

Motor:This kit uses an 800W spindle motor, which has a strong power suitable for engraving harder boards. It can engrave some metals by changing the corresponding tools

Speed:The spindle kit can increase the engraving machine’s speed to 10,000-30,000 RPM, allowing the engraving machine to complete engraving tasks more quickly

Control:The edge trimming machine kit integrates the speed adjustment function into the spindle, making it more convenient to adjust the speed and reduce the footprint

Adaptation:It can be used on machines above TTC450. On models of TTC6050 and TTCH series, the spindle can only be manually turned on for the time being

¶ Kit details

¶ Vacuum cleaner kit

The vacuum cleaner kit is an upgrade component specially designed for CNC machine models, aimed at improving the working environment during the engraving process. This kit can be conveniently installed on the spindle of the CNC machine to achieve synchronized operation of engraving and vacuuming, greatly reducing the dispersion of dust onto the table and into the air, improving air quality, and protecting the health of the operator. Here is an introduction to this kit:

Adapt to the spindle:The vacuum cleaner kit can be installed on both 775 spindle motors and 500W air-cooled spindle motors.

Brush:The front brush can be replaced according to different spindles.

Working Method:The vacuum cleaner kit has two modes of operation, which can be manually activated and automatically activated.

¶ Kit Details

¶ Air-cooled kit

|