The TTC450 engraving machine is a computer-controlled device that utilizes high-speed rotating tools for cutting. It primarily consists of control systems, mechanical structures, cutting tools, and drive systems. It can engrave and cut various materials such as wood, acrylic, stone, plastic, and more.

|

¶ Control System

The control system is the core component of the engraving machine, comprising a computer, numerical control system, programming software, and more. Operators can design and program on the computer, import the desired engraving patterns into the numerical control system, and transmit instructions through the controller to control the machine, allowing it to cut along the predetermined paths.

|

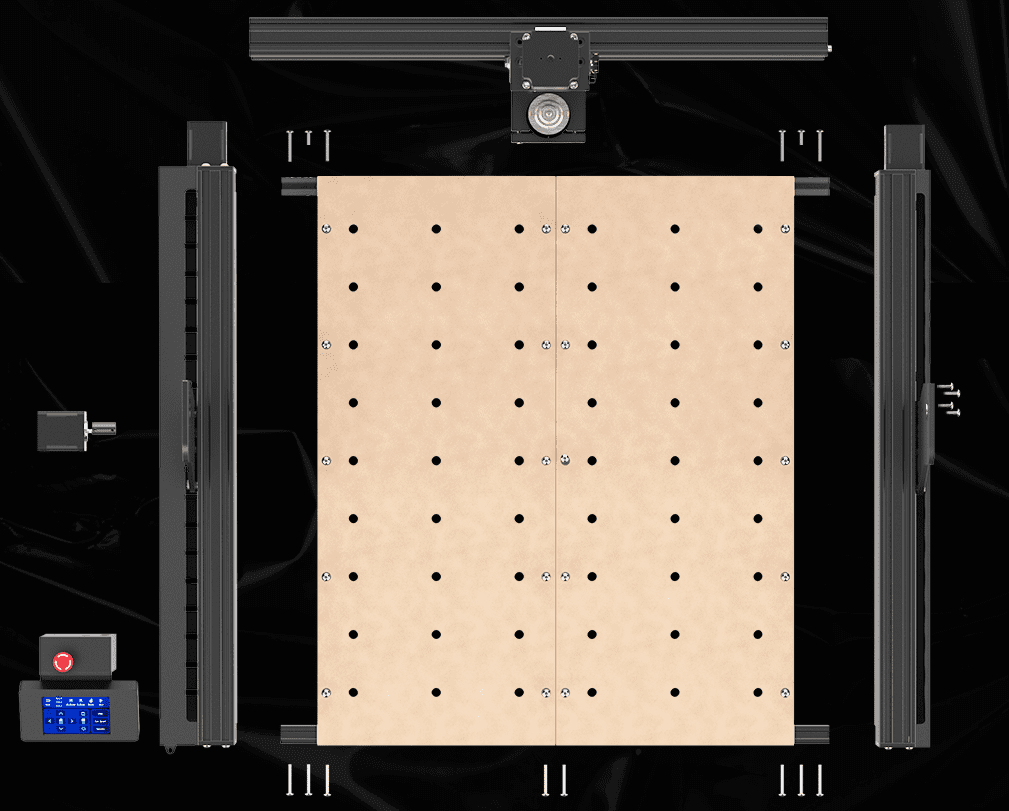

¶ Mechanical Structure

The mechanical structure is the main component of the engraving machine, consisting of the worktable, lead screw, drive system, and more. The frame serves as the support structure of the engraving machine, while the worktable functions as the platform for mounting workpieces and cutting tools. The motion system and drive system are crucial for controlling the movement of the cutting tool.

|

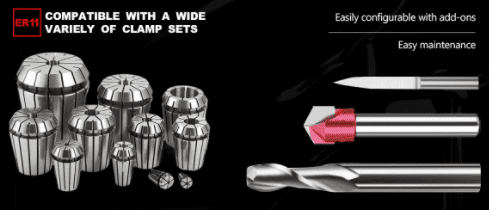

¶ Cutting Tools

The cutting tool is the core component of the engraving machine, comprising the tool itself and tool holders. The tool is the primary instrument used for cutting in the engraving machine. It comes in various types such as carbide tools and high-speed steel tools, depending on the material being processed and the desired engraving effect.

|

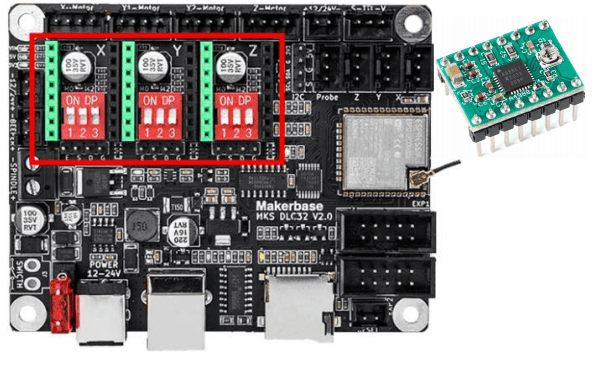

¶ Drive System

The drive system is a vital component of the engraving machine, utilizing motors, reducers, couplings, and more for transmission and control. The drive system enables the cutting tool to rotate and move at high speed along predetermined paths, completing various complex engraving and cutting tasks.

|