¶ SK1 Sealing Kit

|

The SK1 printer enclosure kit is specifically designed for the SK1 3D printer, providing an outer casing for enhanced functionality and reduced printing limitations.

Enclosure: This is the primary component of the kit, consisting of a custom-designed casing that improves the printer’s versatility and greatly reduces printing constraints.

Design: The enclosure is typically tailored to the dimensions and shape of the SK1 printer, ensuring a perfect fit and providing optimal protection.

Ventilation: Consideration is given to ventilation openings to ensure adequate airflow for long printing sessions and stable internal temperatures, preventing overheating.

Convenience:: The kit design may also include convenient features for easy access to interfaces, feeding, and other operations while maintaining protection for the printer’s internals.

The design of the SK1 printer enclosure kit not only enhances printing quality and effectiveness but also prolongs the printer’s lifespan and ensures proper storage when not in use.

¶ Kit Details

- Brief Introduction

- Installation Instructions

- Installation video

- Suite Tutorial

- Common Fault Information

- Daily Maintenance

¶ SK1 Camera Kit

|

The SK1 3D printer camera kit is specifically designed for use with the SK1 3D printer, providing users with monitoring and time-lapse photography capabilities. Here are some components and features that may be included in such a kit:

Camera: The kit includes a camera for real-time capturing of the printing process. These cameras are high-definition, capable of capturing clear images.

Bracket: A bracket is included for mounting the camera. The bracket is designed to be sturdy and reliable, capable of securely positioning the camera next to the printer.

Connecting cable: Used to connect the camera to the printer’s mainboard USB port. The cable has sufficient length to allow the camera to be installed in the optimal position.

Klipper backend: Provides a complementary monitoring interface, allowing users to view real-time printing processes from remote devices. This Klipper backend features a range of functions, such as starting, pausing, and stopping prints, as well as image capture and storage capabilities.

Such a camera kit provides users with convenient monitoring capabilities, enabling them to view the real-time status of the 3D printing process anytime, anywhere, for better management and control of printing tasks.

¶ Kit Details

¶ SK1挤出机套件

|

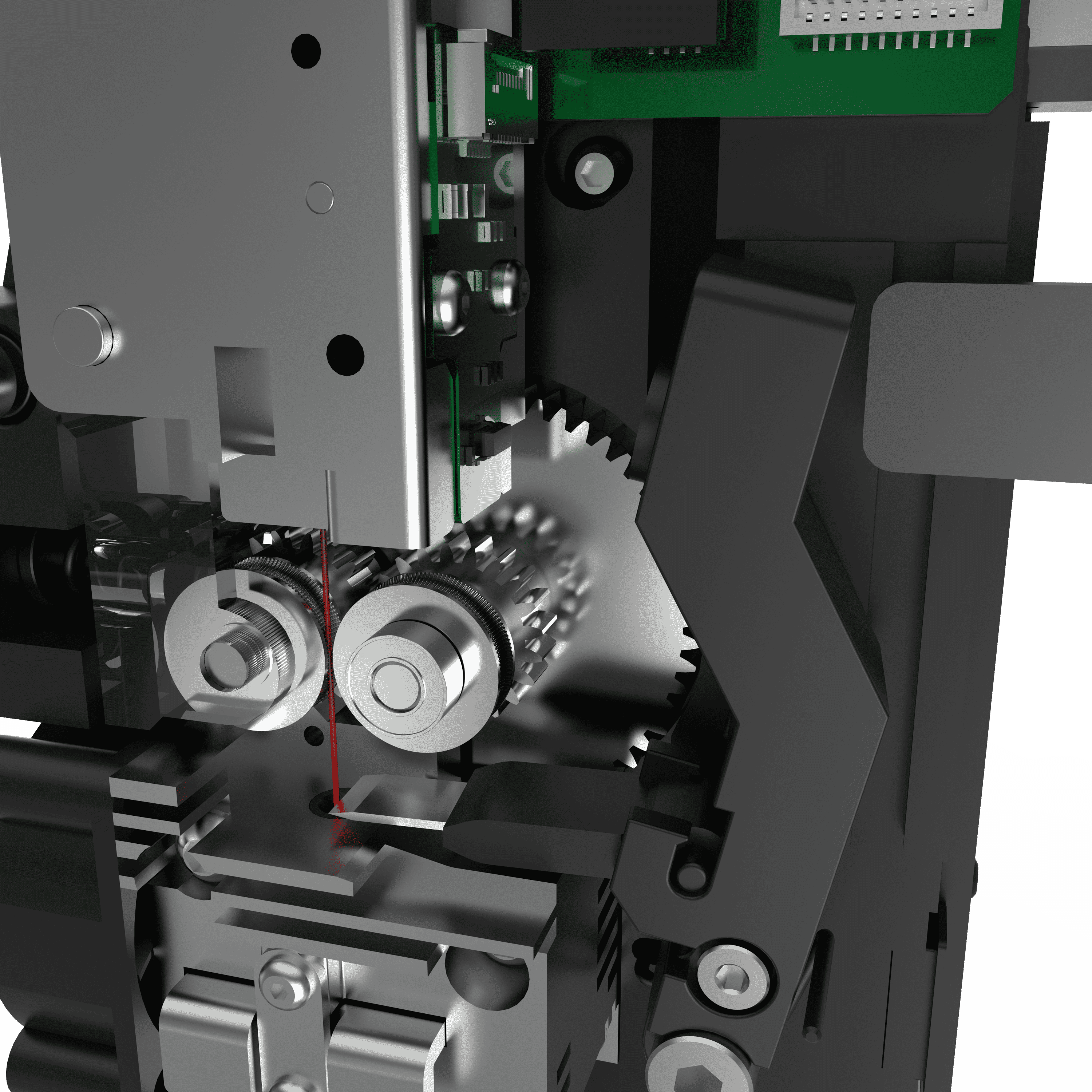

The SK1 Extruder Kit is a high-performance extrusion system specifically designed for 3D printers. It integrates the latest hardware and smart features to provide enhanced printing precision, ease of use, and a flexible modular design. This kit is suitable for a variety of 3D printer users, especially those who require efficient, accurate, and stable printing.

intro:The SK1 Extruder Kit draws inspiration from users' urgent needs to improve printing efficiency and reduce clogging. Most printer users encounter issues with clogged extruders, leading to interrupted prints and difficult maintenance, especially when changing filaments, where manual handling of residual material strands is required. To tackle these challenges, the SK1 adopts a brand-new control scheme that not only increases extrusion flow rate and enhances extrusion speed but also significantly improves the overall stability and precision of printing. Most importantly, the new cutting blade feature greatly simplifies retraction operations, effectively avoiding material residue in the printer and eliminating the problem of extruder clogging. This smarter and more reliable extrusion system is suitable for high-end users and those requiring rapid printing speeds。

High speed printer:The SK1 extruder head significantly increases the extrusion flow rate, and with the enhanced heating block, users can still maintain stable print quality even during high-speed printing.

TPU and other flexible material users:The SK1's cutting blade feature and flow compensation technology ensure that flexible materials can be easily retracted, ensuring smooth printing.

Multi-material switching needs users:The modular design with quick-release functionality allows users to easily maintain the extruder head, especially when frequent changes of different types of materials are required, greatly improving operational efficiency.