¶ Advanced Relief Sculpting Tutorial

This tutorial explains the method of performing 3D relief processing in Kiri.moto.

Learning Suggestions: To facilitate understanding of the following content, we recommend that you complete:

- First-time User Tutorial (Basic Operations and Interface)

- Machine Tool Configuration Tutorial (Add Configuration Tutorial)

- Tool Addition Tutorial (New Tool Tutorial)

- 2D Plane Machining Tutorial (Basic Tool Path Programming)

¶ Preface:

Since the current version of Kiri.moto does not support exporting the roughing and finishing tool paths separately as independent NC files, please use the following method:

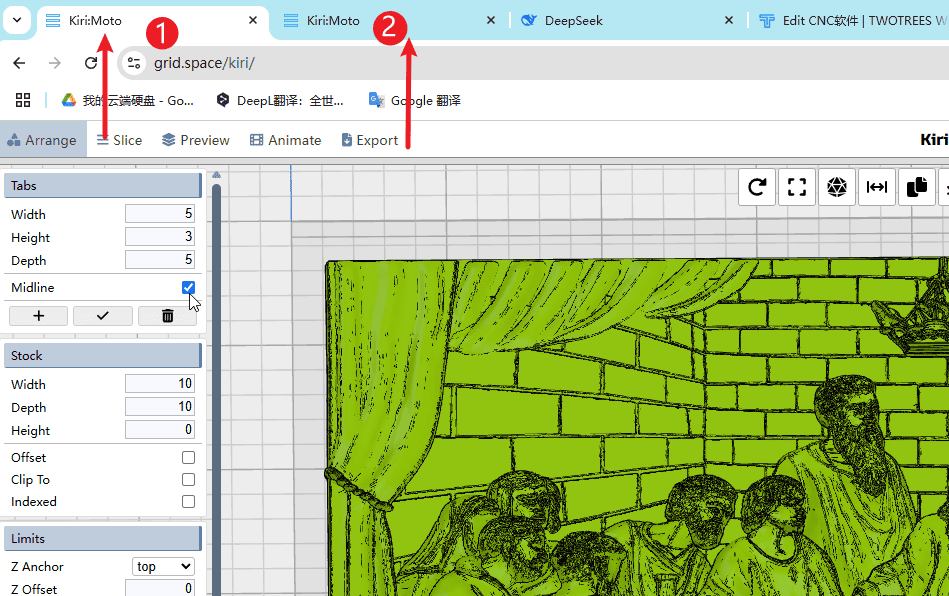

Start two Kiri.moto instances: Open two separate Kiri.moto browser tabs or windows simultaneously.

Set separately:

In the first instance, configure and generate the rough machining tool path.

In the second instance, configure and generate the refined tool path.

Key synchronization settings: Make sure that the following parameters in both instances are exactly the same:

Raw material dimensions (Stock Material Dimensions)

Work Coordinate System Origin

此操作是保证粗、精加工精准对齐的基础。

Step 1

Perform the operations according to the sequence numbers.

- 1.Select a page for rough programming processing

- 2.The second page undergoes refined programming

|

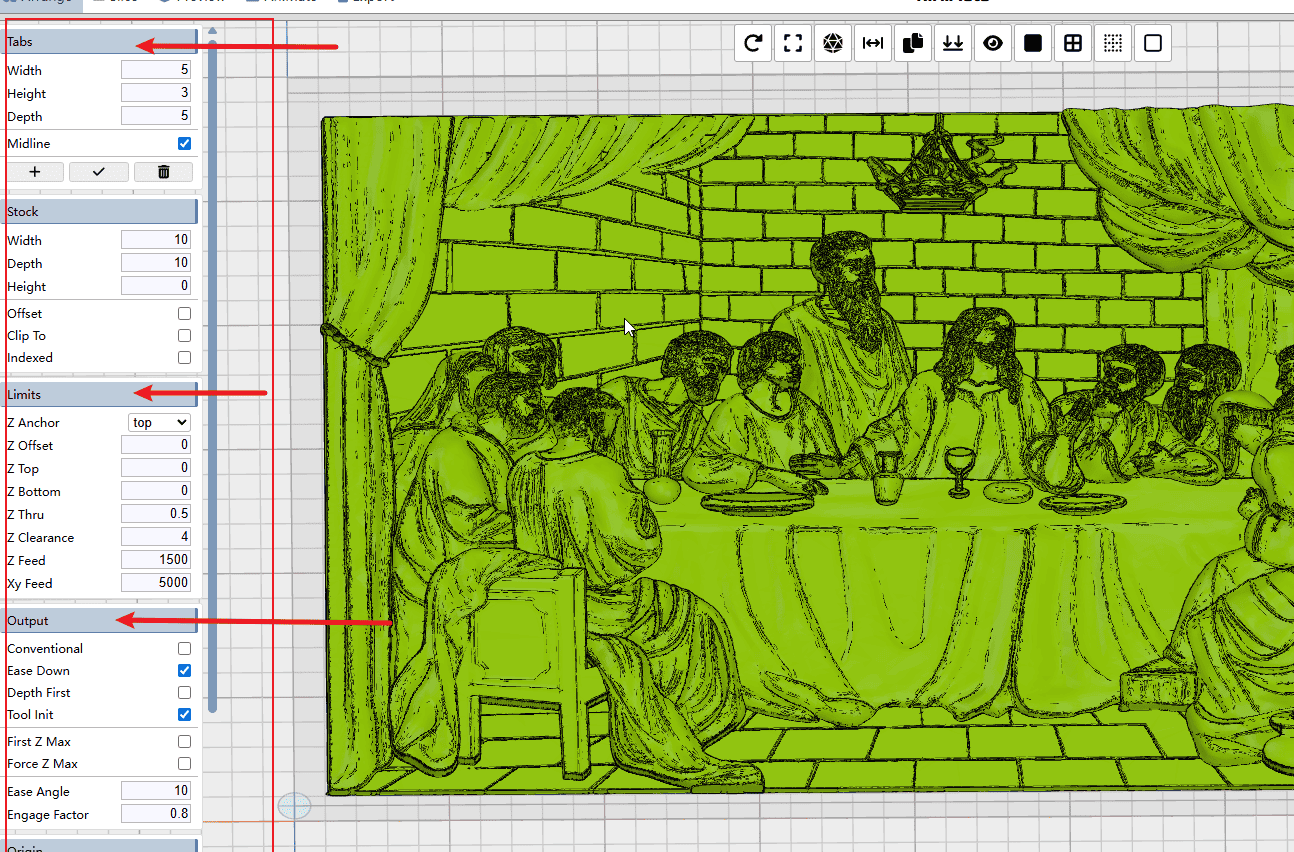

Step 2

The settings bar on the left can be used in the same way as in the 2D programming tutorial (Note: You can set it yourself, but make sure the settings for roughing and finishing are consistent)

|

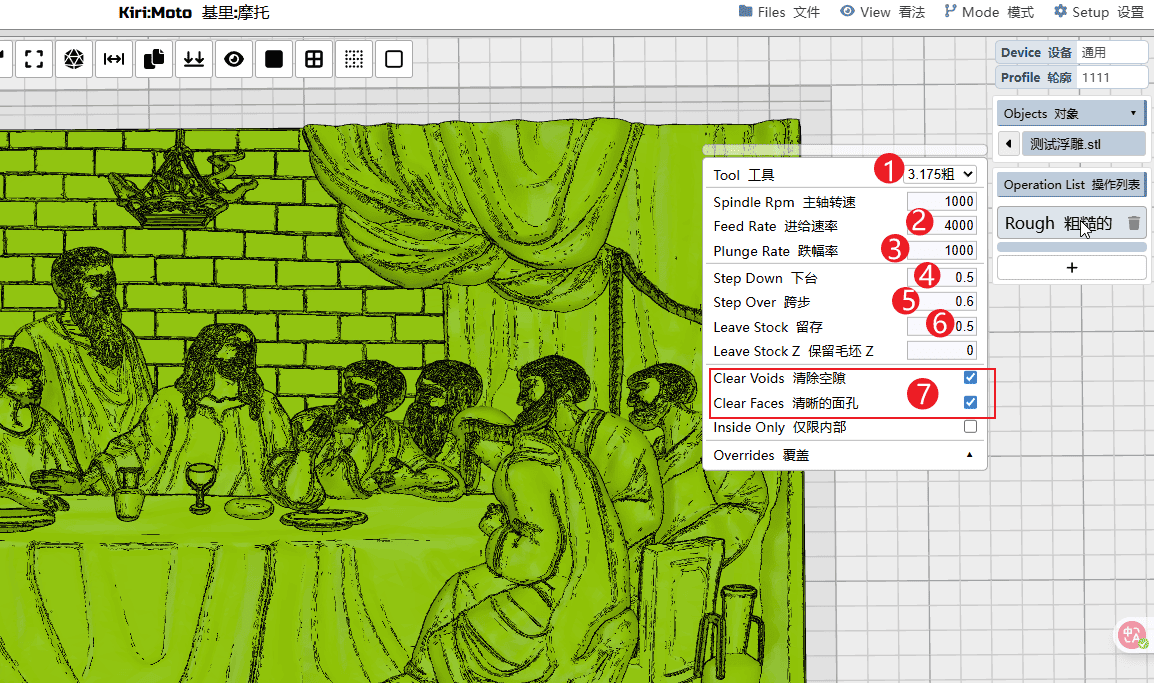

Step 3

Coarse processing settings,Perform the operations according to the sequence numbers.

- 1.After selecting the rough machining instructions, first choose the face mill cutter required for the rough machining.

- 2.Set the XY feed rate

- 3.Set the Z-axis feed rate for retraction

- 4.Set the depth of each downward cut

- 5.Set the row spacing for each cutting path

- 6.Set the margin properly to facilitate subsequent fine processing. A margin of around 0.5 is sufficient.

- 7.Just check the boxes of the options you want to select.

|

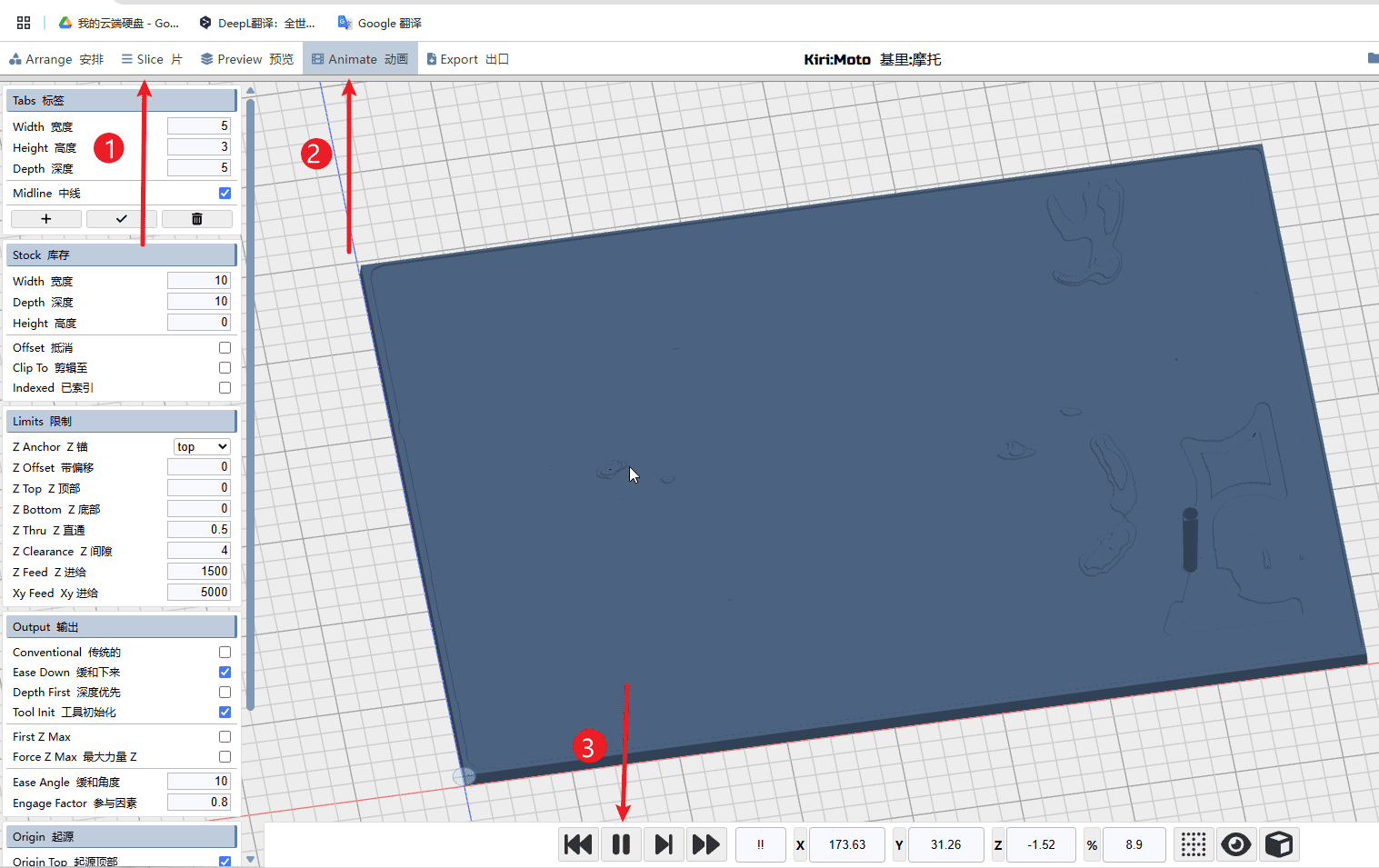

Step 4

Perform the operations according to the sequence numbers.

- 1.Click on the slice to start programming and wait for it to complete.

- 2.Click simulation

- 3.Click to play and check if the knife path is normal

|

Step 5

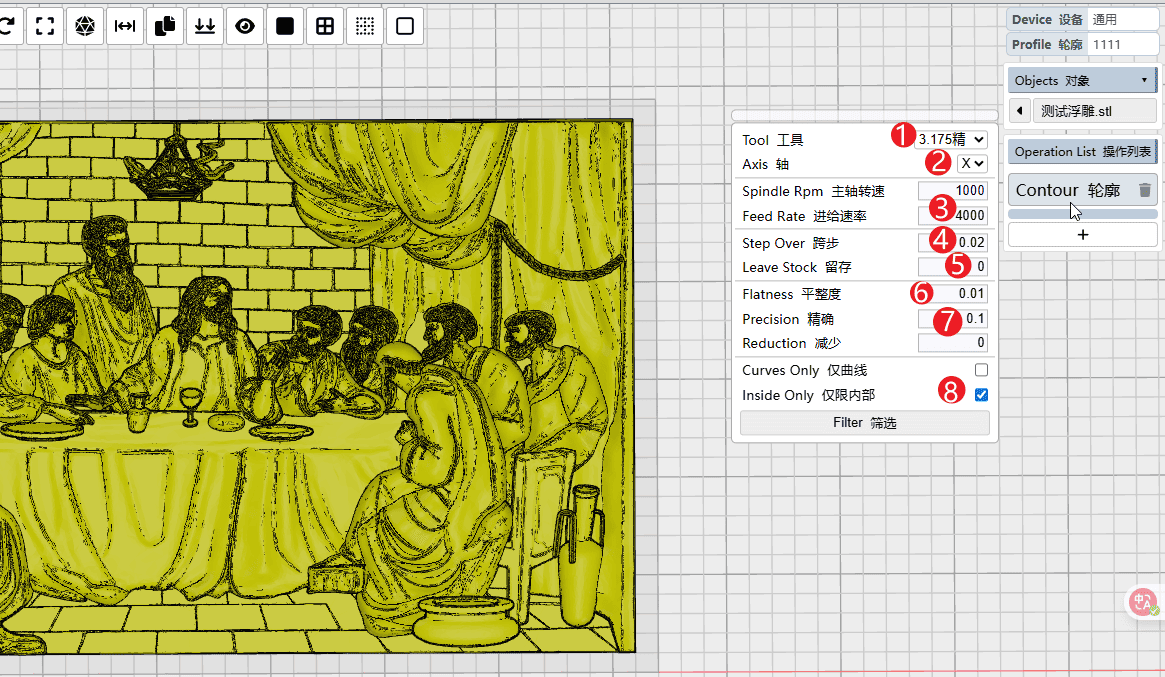

Finishing processing settings,Perform the operations according to the sequence numbers.

- 1.Select the contour command. First, select the V-shaped milling cutter that needs to be finely processed.

- 2.Set the direction of the tool path movement

- 3.Set the XY feed rate

- 4.Set the step distance for movement, and the machining allowance setting should be within 0.5.

- 5.Finishing processing can do without setting up allowances.

- 6.The recommended setting for flatness is 0 - 0.01 (you can also set it yourself. The smaller the value, the more it will ignore minor protrusions).

- 7.The recommended setting for precision is 0.1.

- 8.Select “Internal Only”

|

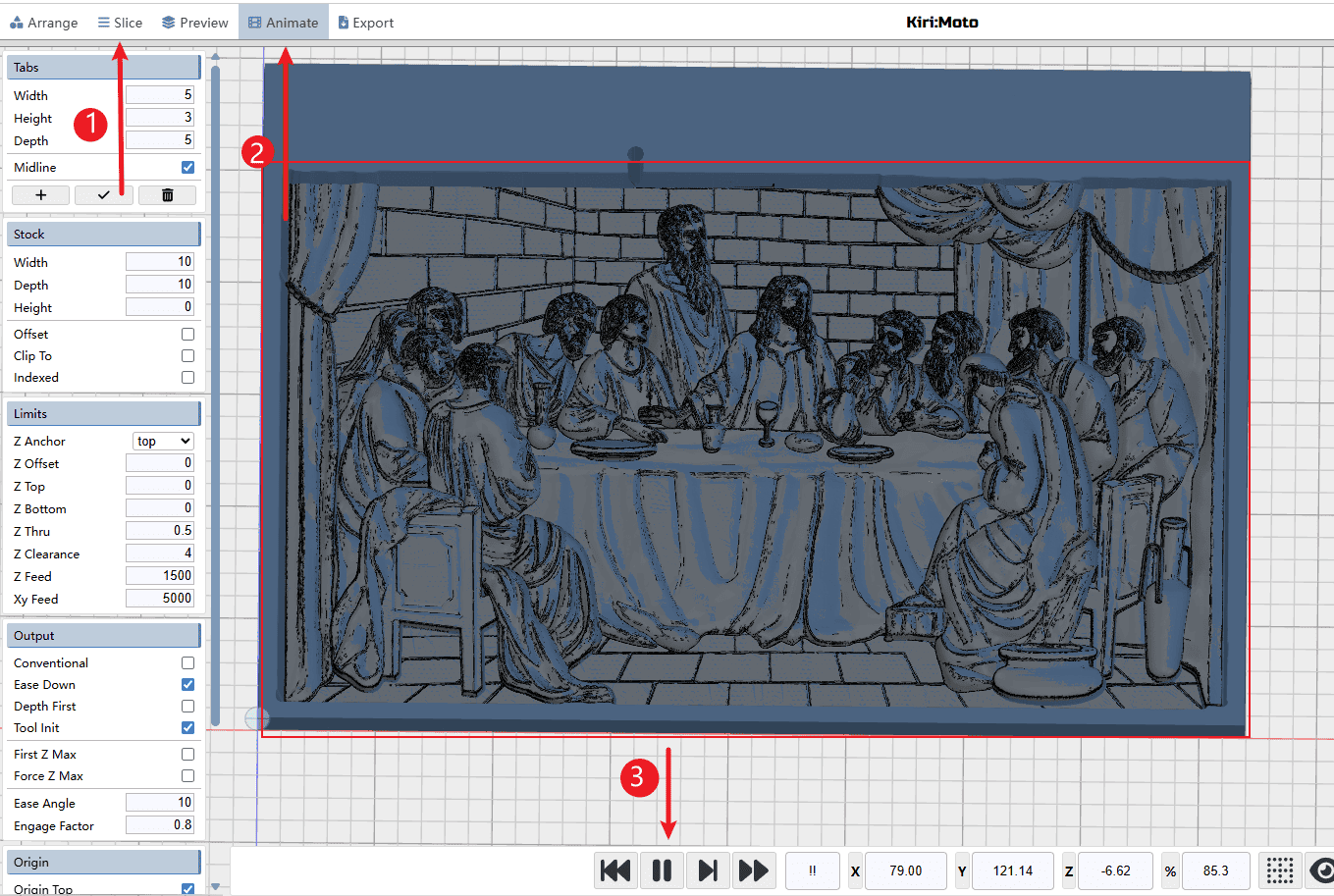

Step 6

Perform the operations according to the sequence numbers.

- 1.Click on the slice to start programming and wait for it to complete.

- 2.Click simulation

- 3.Click to play and check if the knife path is normal

|

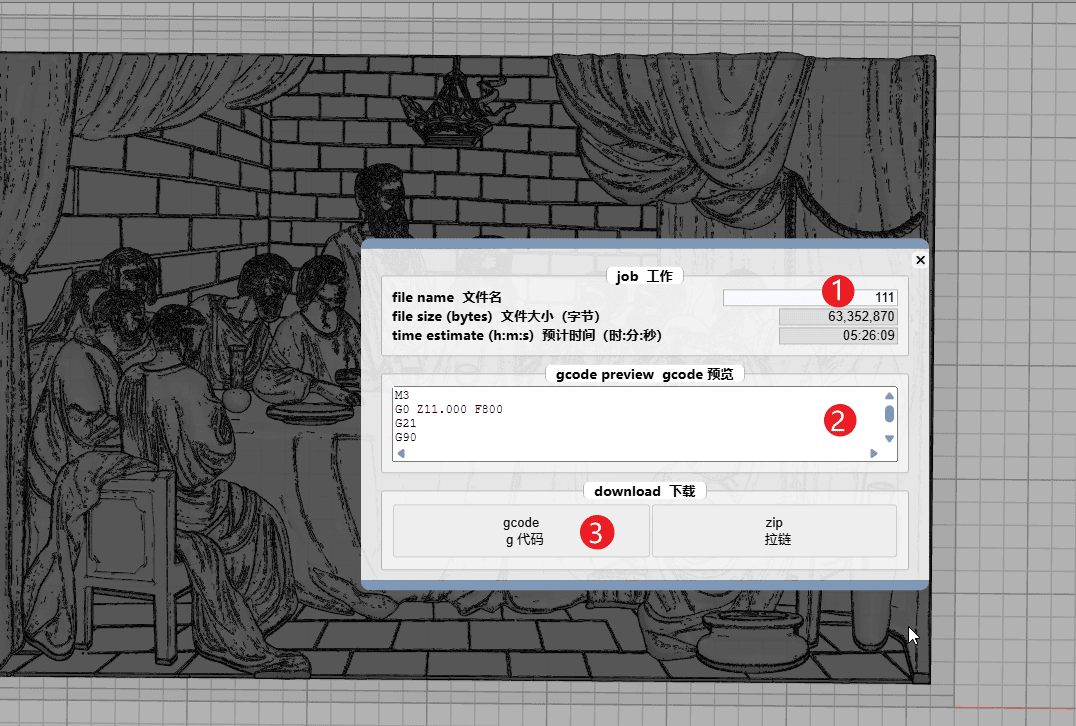

Step 7

Perform the operations according to the sequence numbers.

- 1.Set the names for rough processing and fine processing separately (to avoid duplicate naming)

- 2.You can preview the G-code.

- 3.Finally, simply export the G-code separately.

|