¶ 3D Relief Sculpting Tutorial

This tutorial explains how to create 3D relief designs in Fusion 360. It involves two machining processes: rough machining and fine machining. When calculating the machining paths, a relatively high amount of computer memory is required. It is recommended to have at least 32GB of memory to avoid system crashes due to insufficient memory during the calculation of the machining paths.

This tutorial is an advanced 3D relief modeling course. If you have no experience in 2D programming, it is highly recommended that you first complete the prerequisite tutorials. Otherwise, you may not be able to understand the principles of processing strategy design.

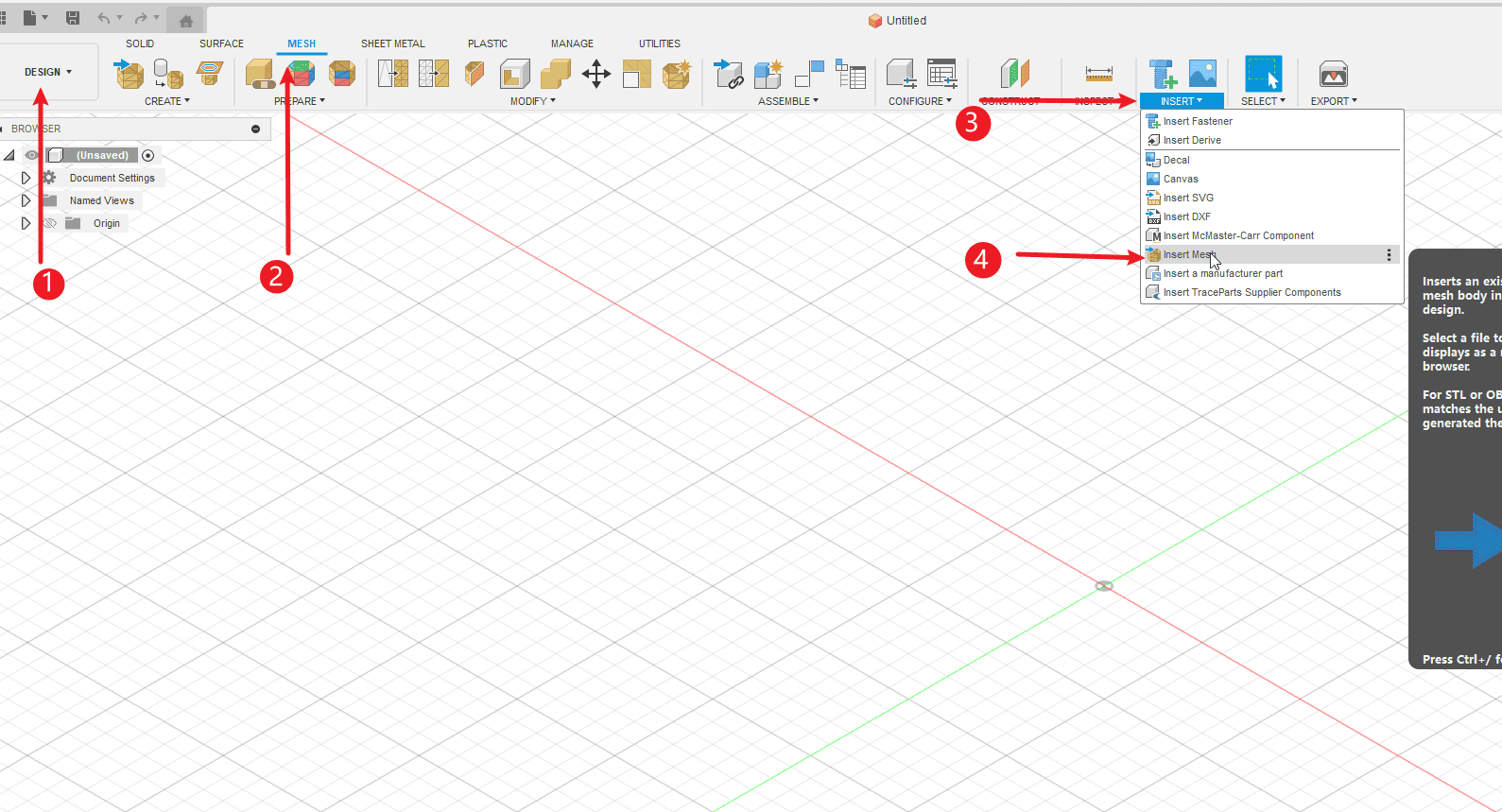

Step 1

Perform the operations according to the sequence numbers.

- 1.Open the design workbench

- 2.Open the grid

- 3.Click “Insert”

- 4.Click to insert grid (

Note: The STL file needs to be opened before insertion. Directly opening it will cause size confusion)

|

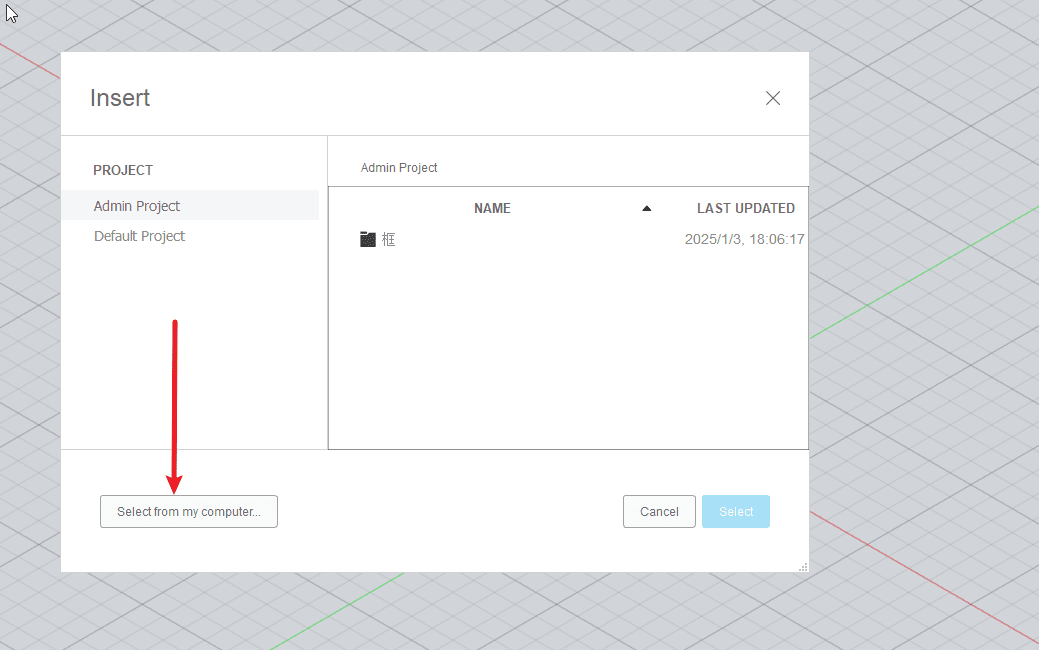

Step 2

- Click to open from the computer.

|

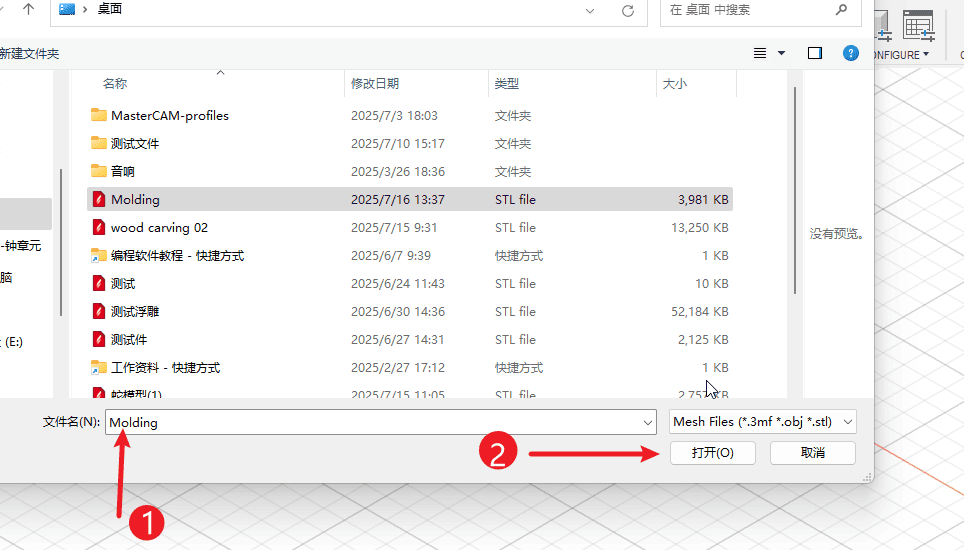

Step 3

Perform the operations according to the sequence numbers.

- 1.Select the files that need to be created

- 2.Click to open

|

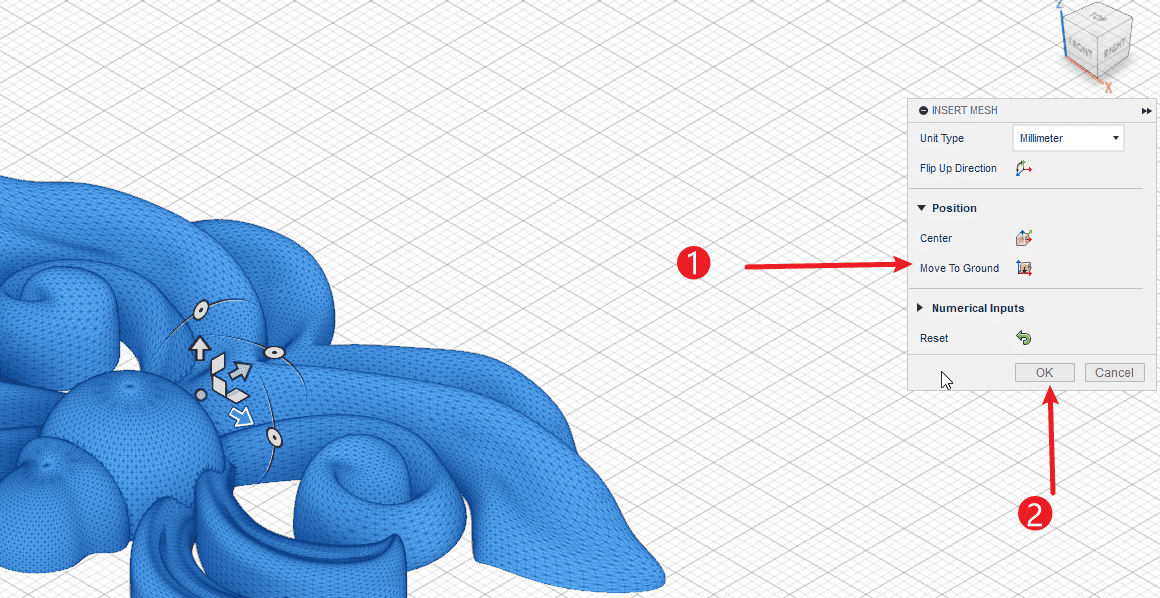

Step 4

Perform the operations according to the sequence numbers.

- 1.Click to place on the ground

- 2.Click “OK”

|

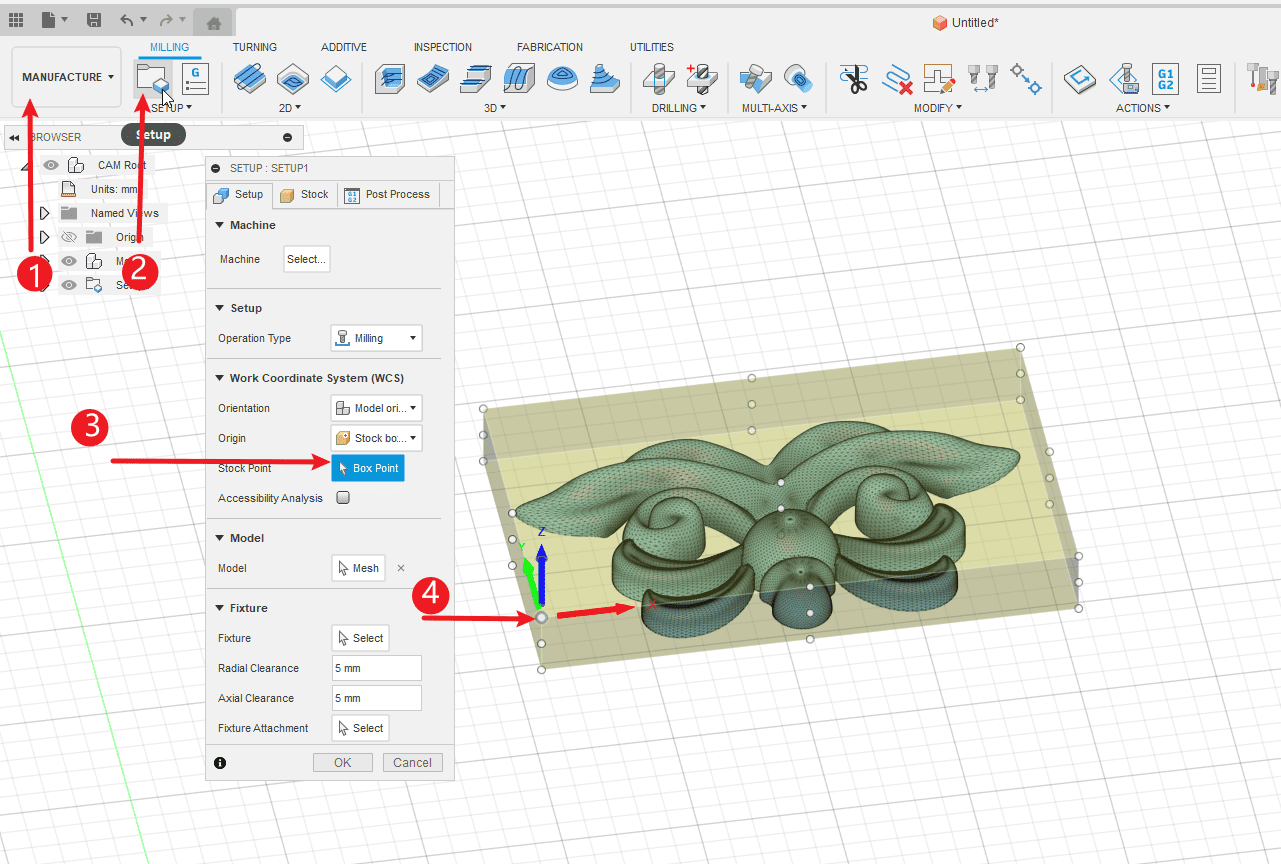

Step 5

Perform the operations according to the sequence numbers.

- 1.Go to the CAM workbench

- 2.Create a new setting environment

- 3.Select the origin

- 4.Set the required origin on the blank itself.

|

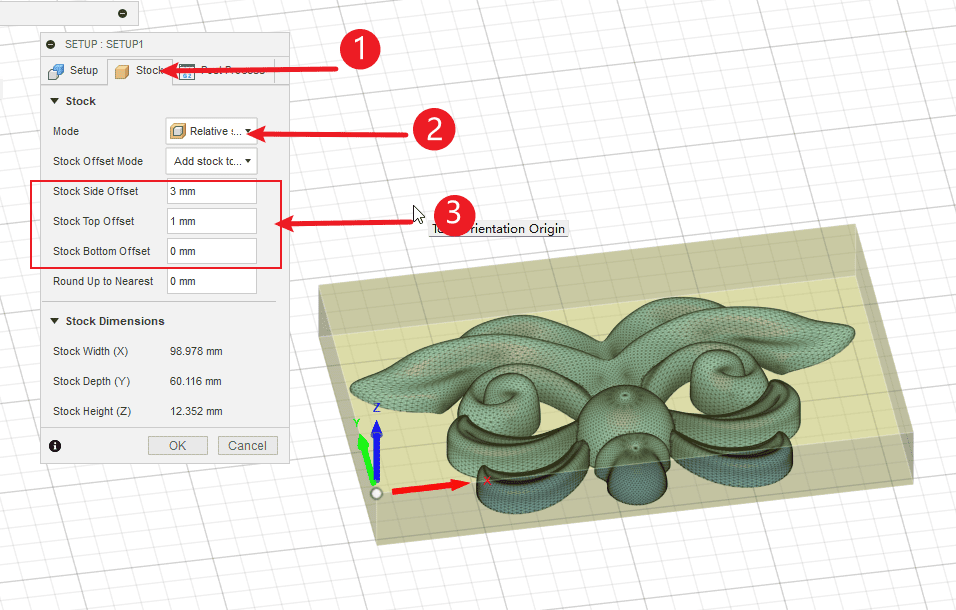

Step 6

Perform the operations according to the sequence numbers.

- 1.Click on the rough setting

- 2.Select relative size offset (or use fixed-size plates)

- 3.Set the offsets for the X, Y, and Z axes in three directions.

|

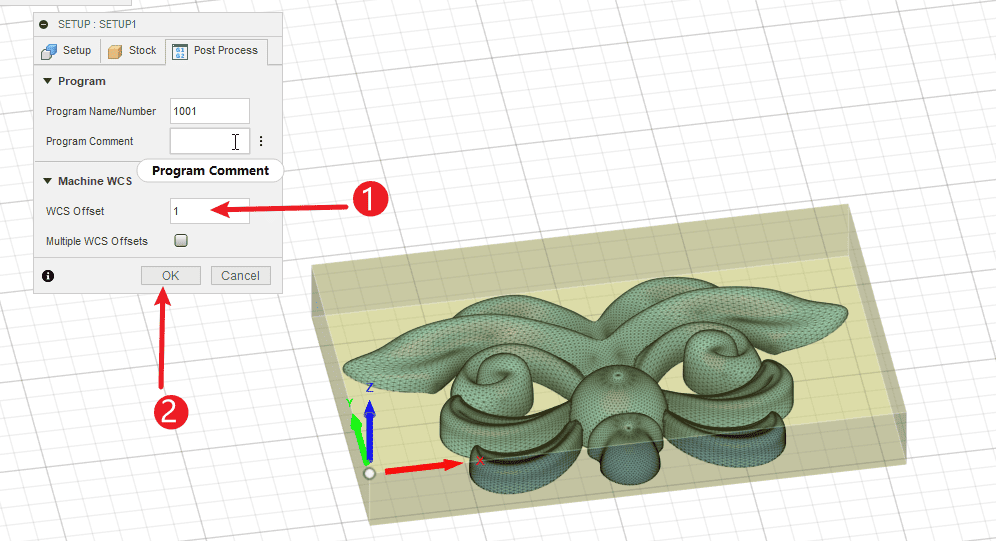

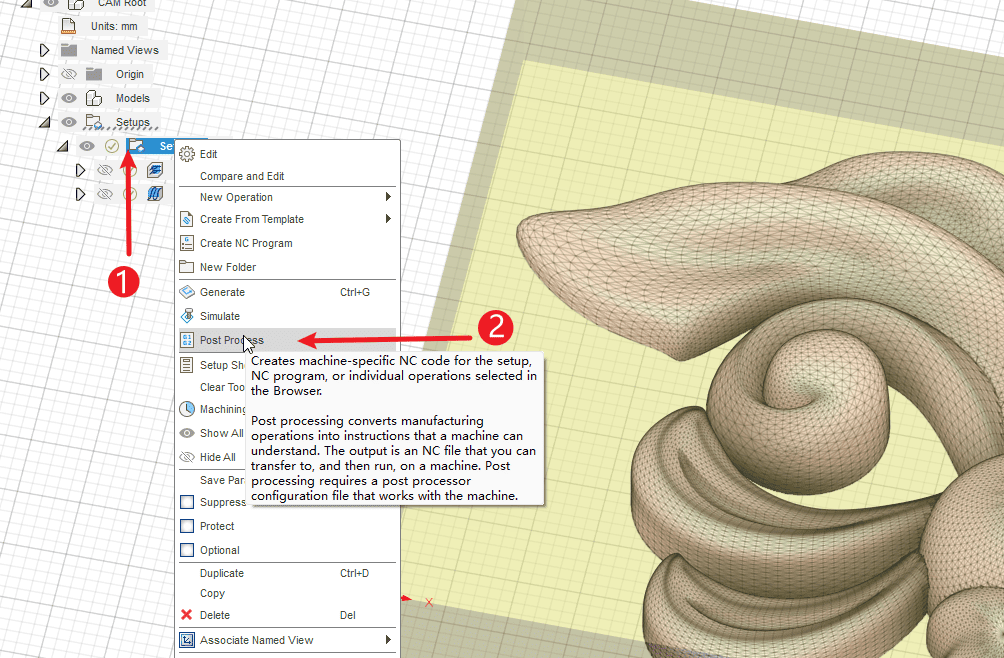

Step 7

Perform the operations according to the sequence numbers.

- 1.Click for post-processing

- 2.Set the WCS offset to 1

|

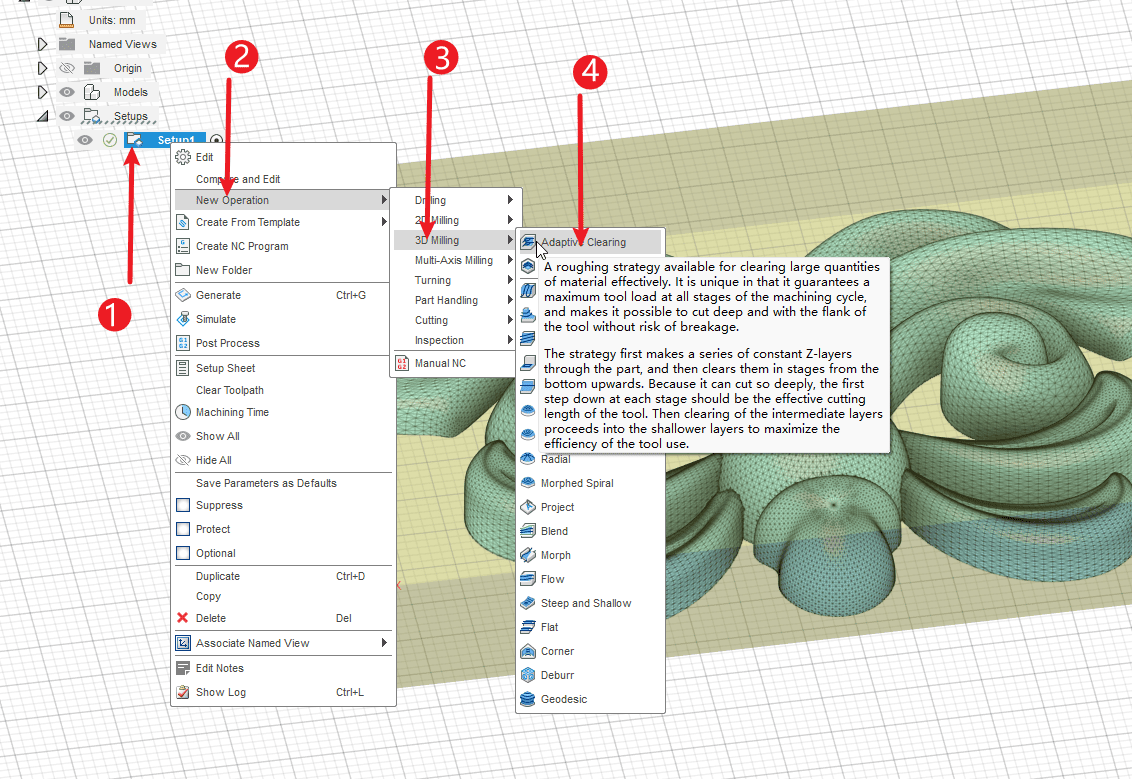

Step 8

Perform the operations according to the sequence numbers.

- 1.Right-click to create a new setting environment

- 2.Click on the “New” operation

- 3.Click on the 3D operation

- 4.Click to add adaptive cleaning

|

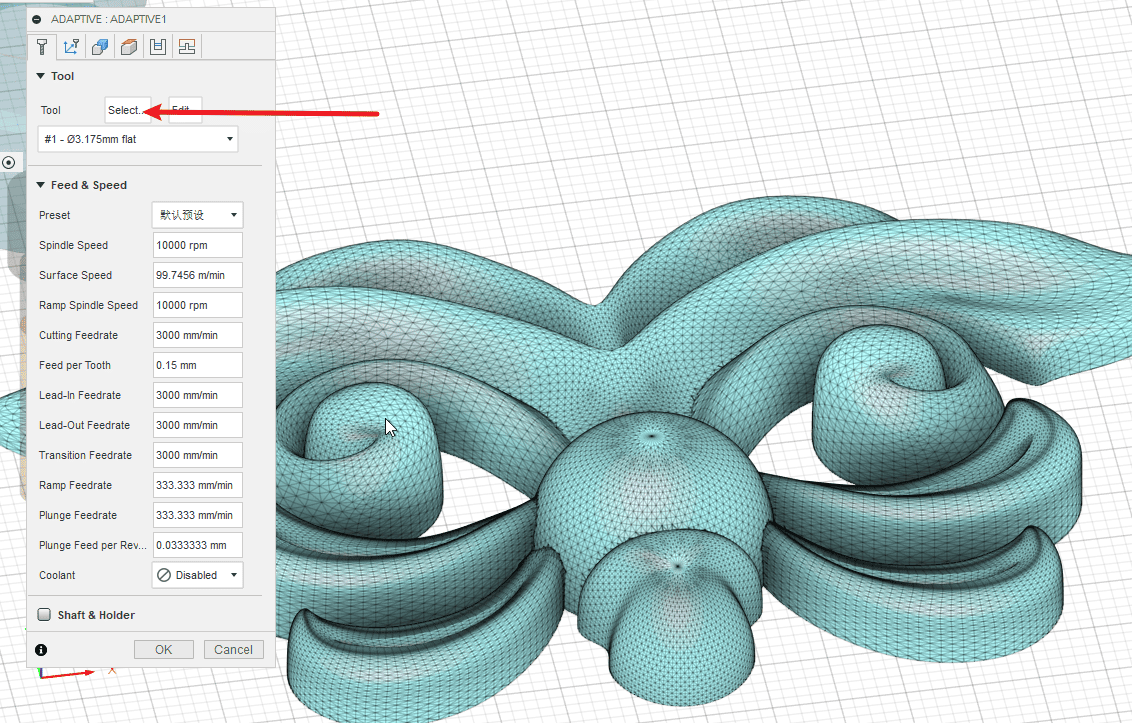

Step 9

- Click on the tool selection, and choose the tool to be used for rough machining.

|

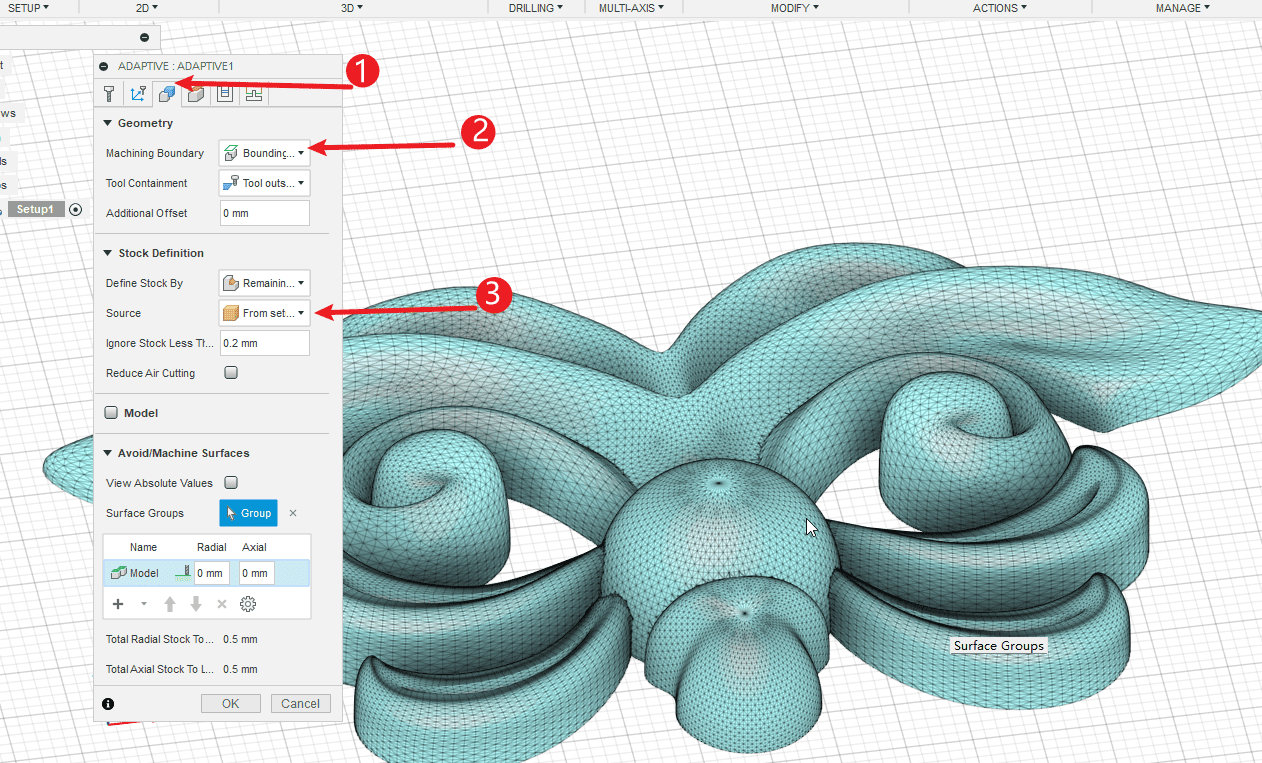

Step 10

Perform the operations according to the sequence numbers.

- 1.Click on the shape

- 2.Process boundary selects boundary box

- 3.Set the “source” in the rough casting definition to start from the setting of the rough casting (this refers to which material to start with. For rough machining, the rough casting is selected; for fine machining, it is selected based on the previous operation)

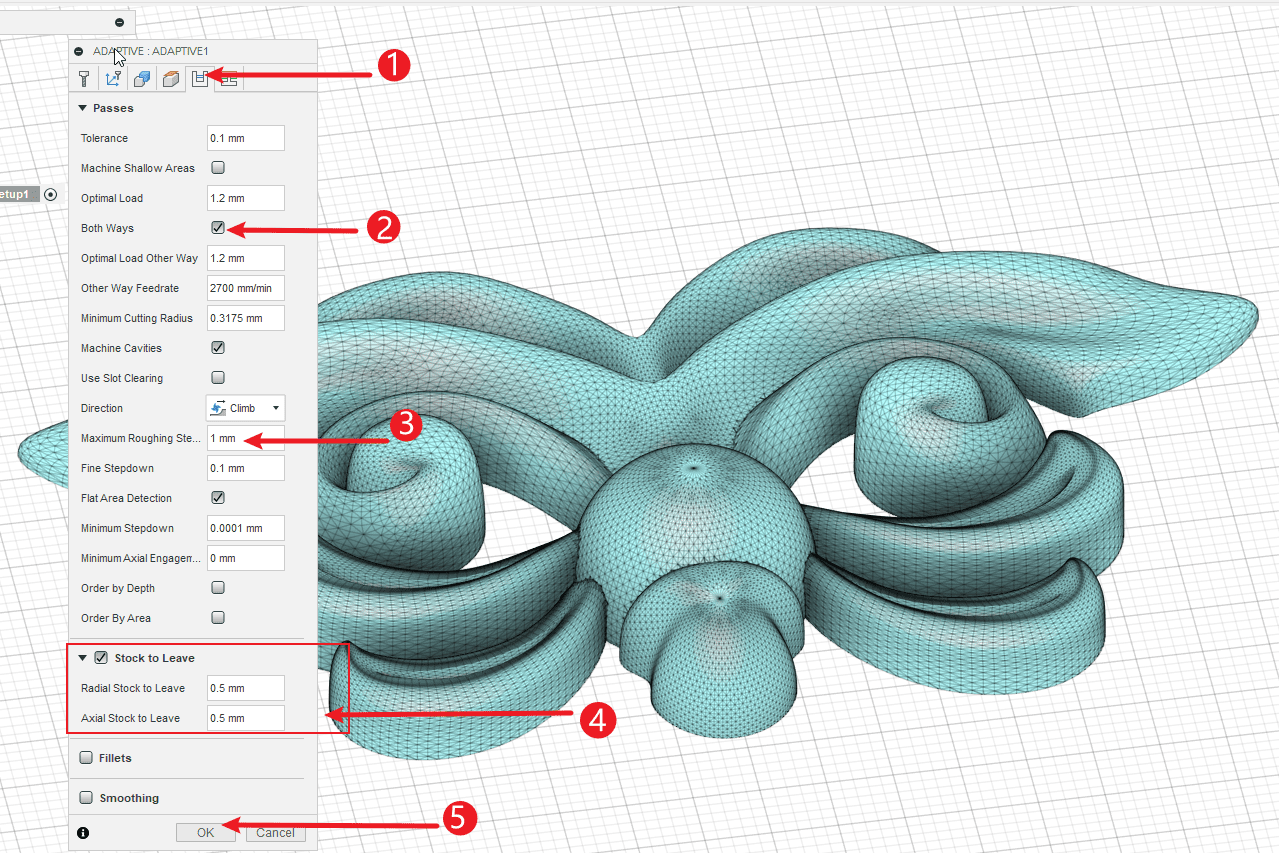

Step 11

Perform the operations according to the sequence numbers.

- 1.Click on the processing path

- 2.Check the option for bidirectional cutting path

- 3.Set the maximum single cutting depth for rough machining

- 4.Set a margin for further fine processing and carving (recommend 0.2 - 0.5)

- 5.Click “OK” to complete the rough processing settings.

|

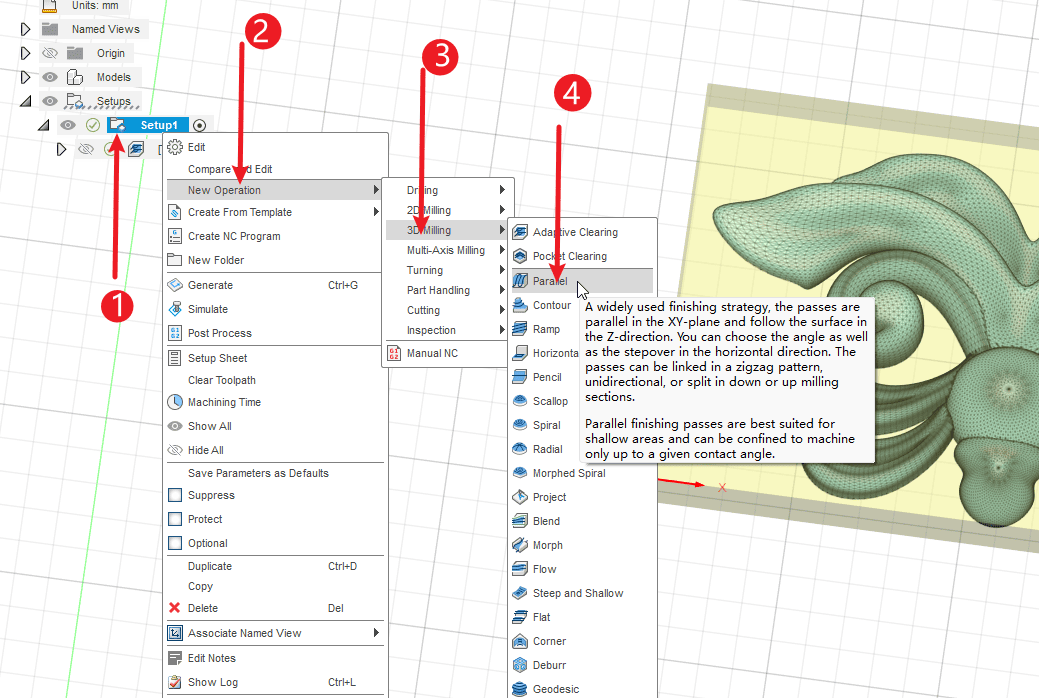

Step 12

Perform the operations according to the sequence numbers.

- 1.Right-click the programming environment and create a refined cutting path.

- 2.Click on the “New” operation

- 3.Click on 3D cutting path

- 4.Click on the parallel strategy

|

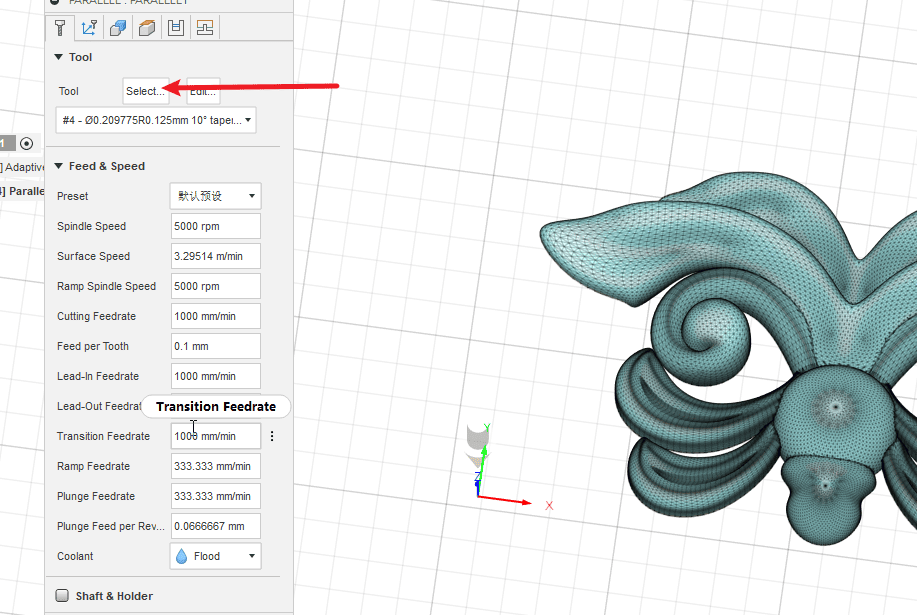

Step 13

- Select the cutting tools for fine processing

|

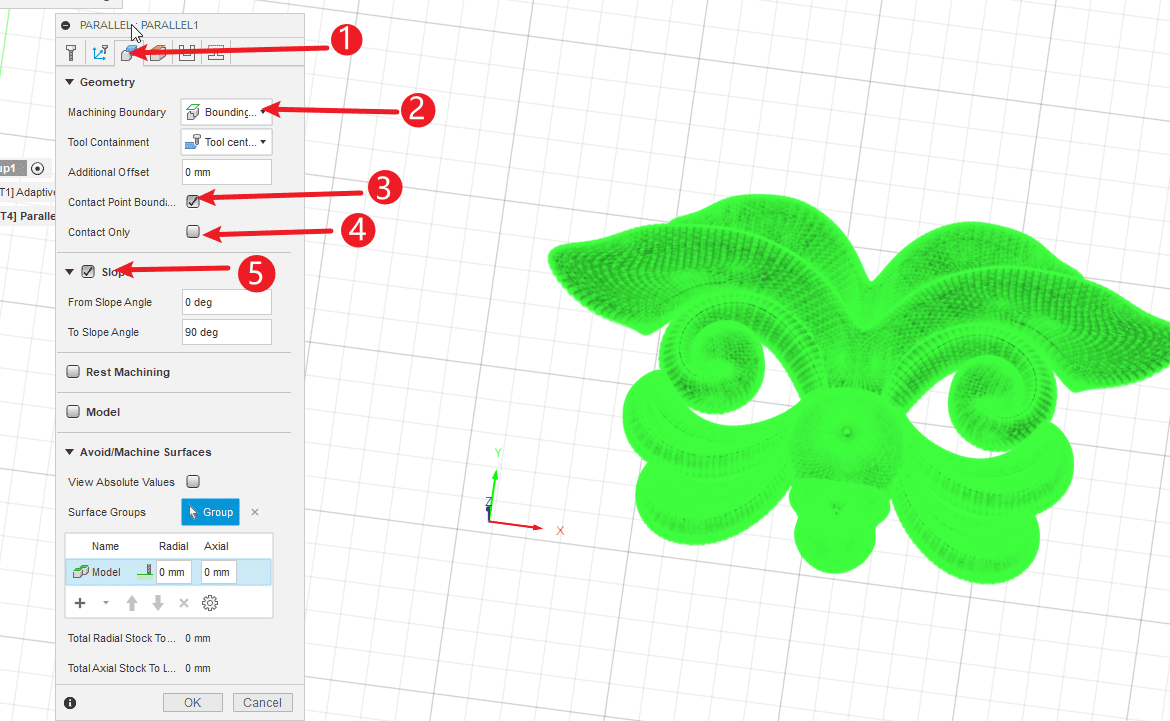

Step 14

Perform the operations according to the sequence numbers.

- 1.Click on the shape

- 2.Process boundary selects boundary box

- 3.Check the contact point boundary

- 4.Uncheck “Only Contact”

- 5.Check the slope settings

|

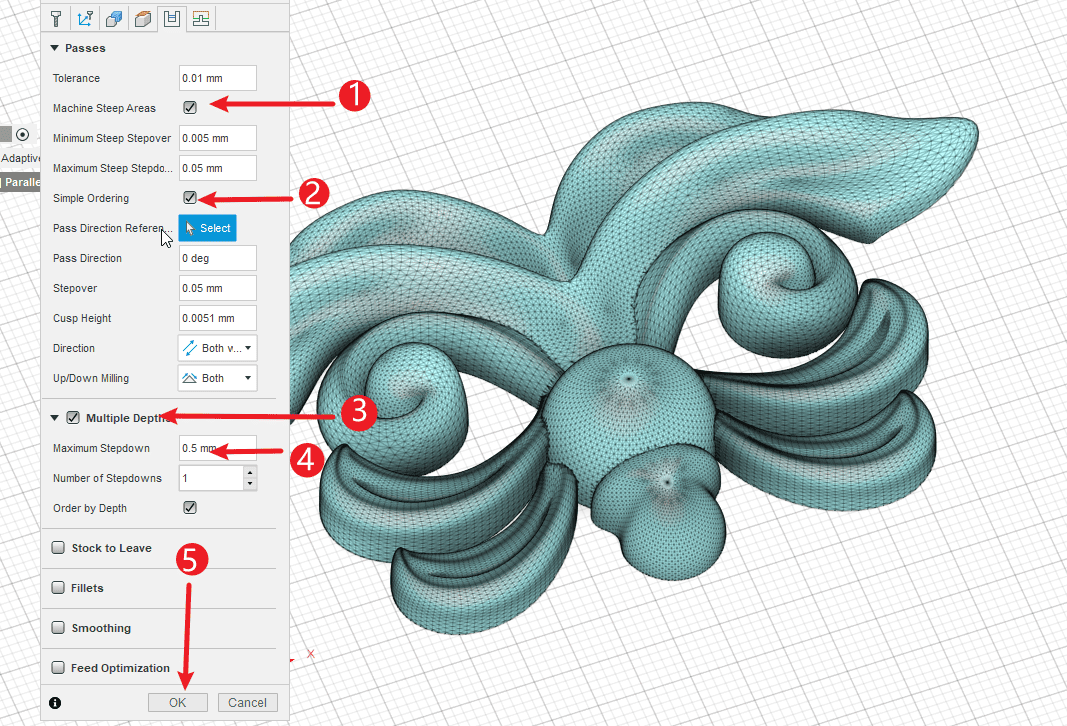

Step 15

Perform the operations according to the sequence numbers.

- 1.Check the option for processing the steep surface area

- 2.Check the “Simple Sort” option

- 3.Select layered milling

- 4.Set the depth of the cutting path for the lower layer (set it to the remaining material after rough machining)

|

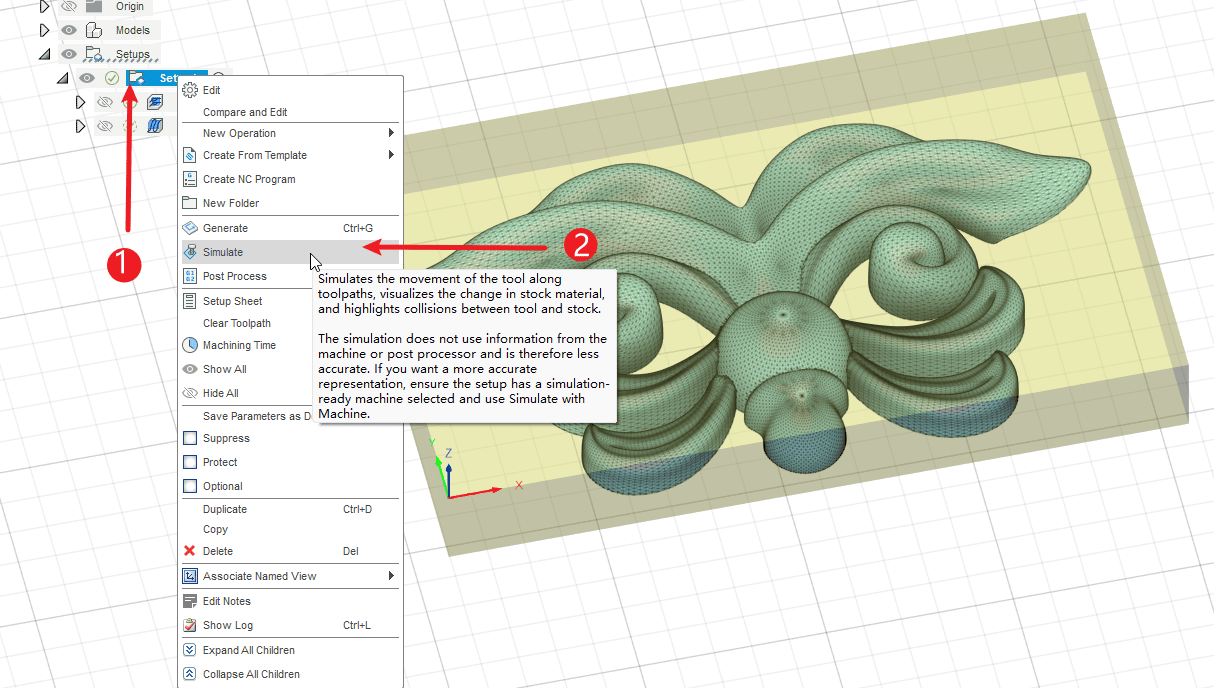

Step 16

Perform the operations according to the sequence numbers.

- 1.Right-click programming environment

- 2.Click on the simulation to observe whether the cutting path is running normally.

|

Step 17

Perform the operations according to the sequence numbers.

- 1.Right-click programming environment

- 2.Click for post-processing

|

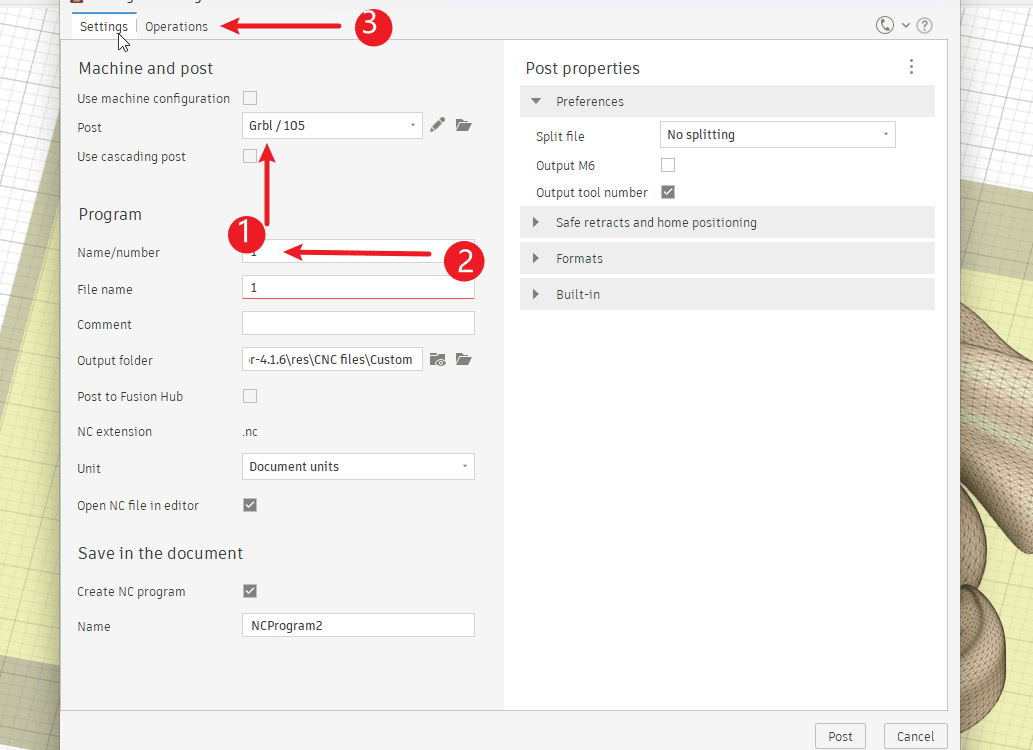

Step 18

Perform the operations according to the sequence numbers.

- 1.Select the post-processor

- 2.Name the file

- 3.During the operation, the two cutting paths were separately exported.

|

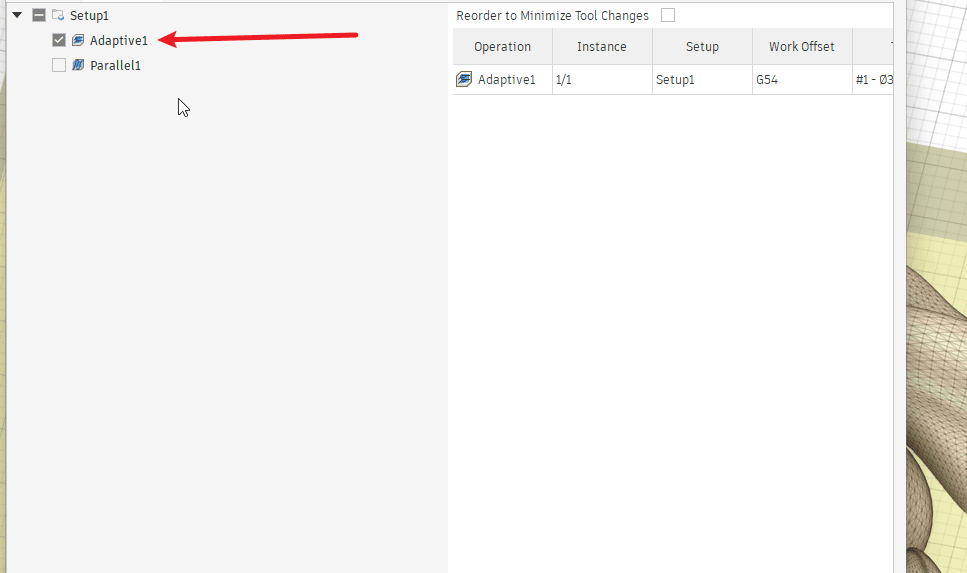

Step 19

- Select one cutting path for post-processing separately, and the same method applies to the other cutting path. The two cutting paths need to be named differently.

|