¶ How to create 3D relief sculptures

This video tutorial explains the method of creating reliefs using the Carveco software.

**Learning Suggestions:**To better master the skills of relief sculpture, we recommend that you first learn the following basic contents:

Tutorial on Tool Creation and Configuration

2D Plane Sculpting Tutorial

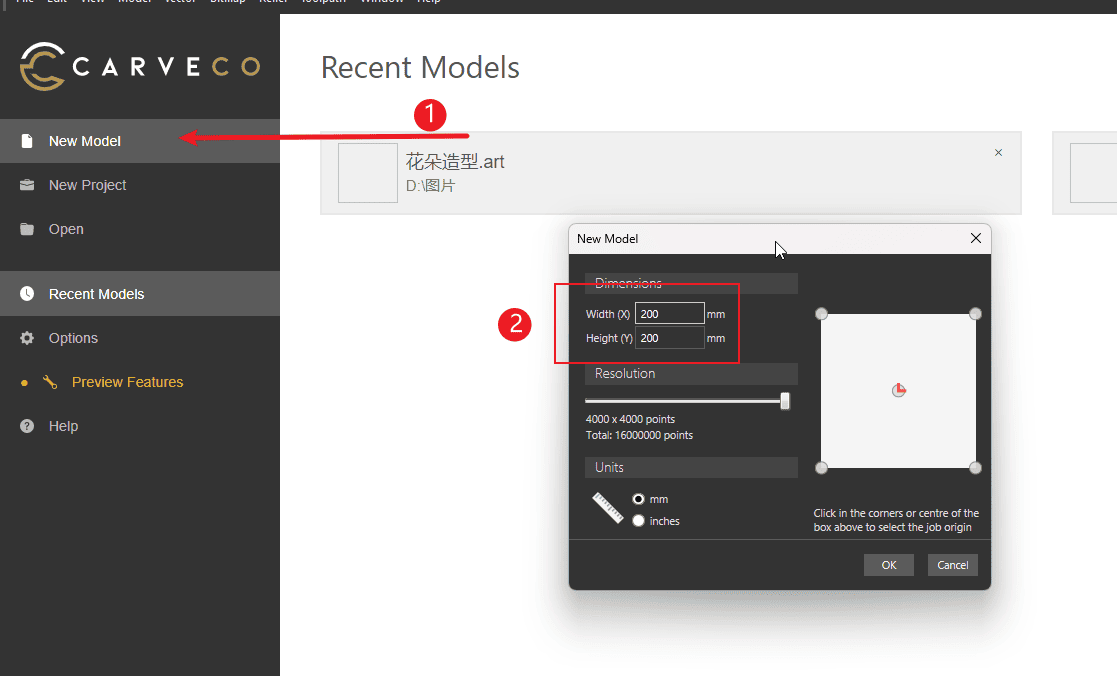

Step 1

Perform the operations according to the sequence numbers.

- 1.Create a new project

- 2.Set the size of the relief to be carved (

Note: The size here should be slightly smaller than the size of the used board, leaving space for the fixation of the press plate)

|

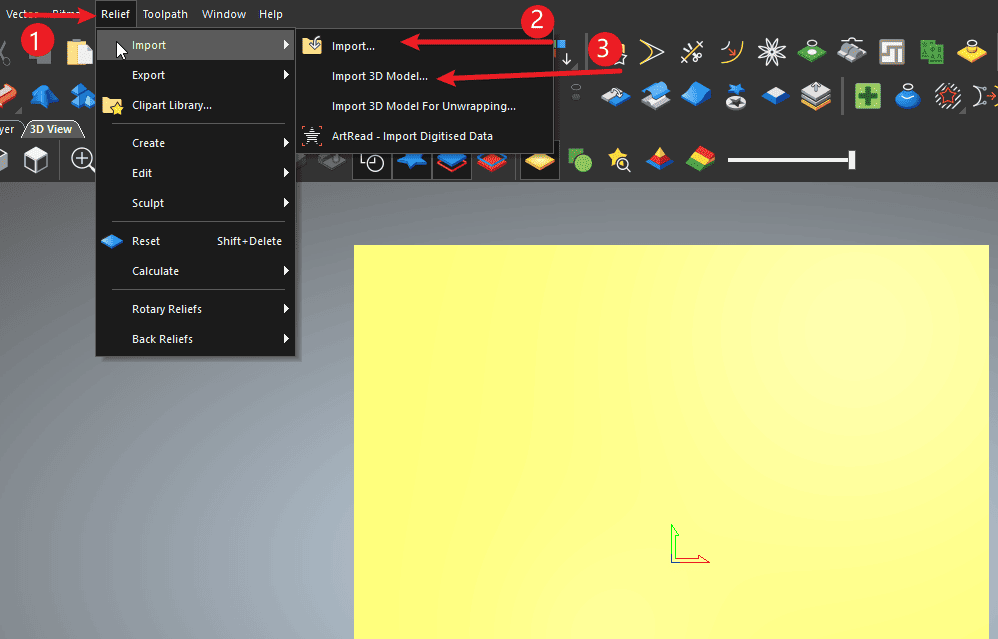

Step 2

Perform the operations according to the sequence numbers.

- 1.Click on the relief.

- 2.Click “Import”, then select the file type for import (you can use grayscale images or STL files)

- 3.Click to import 3D file

|

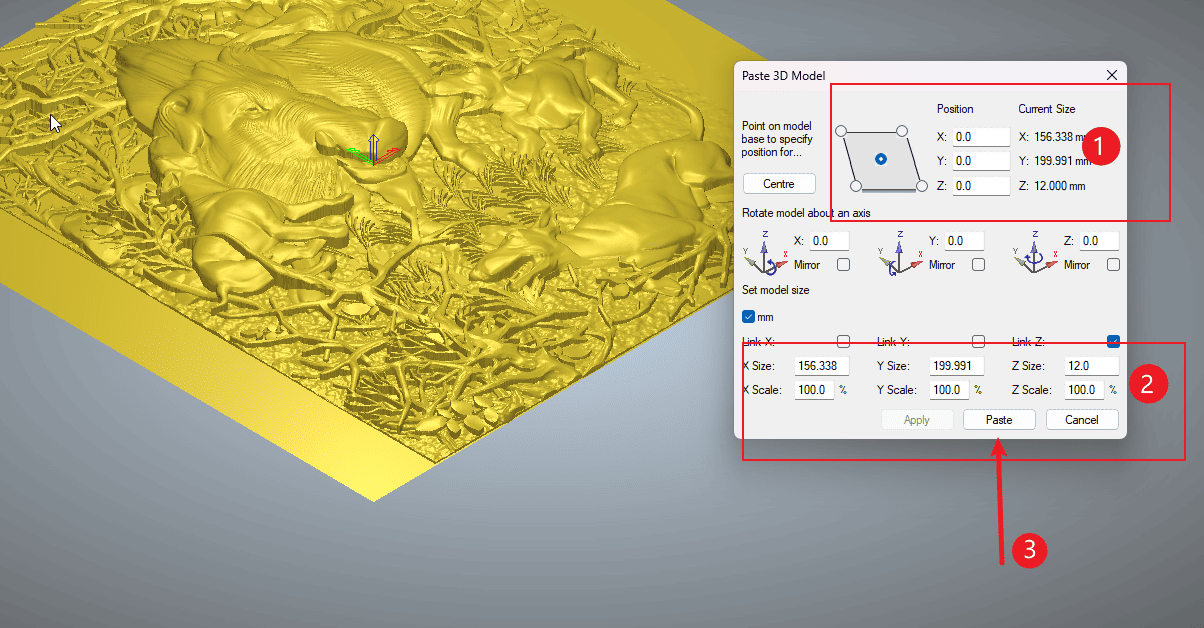

Step 3

Perform the operations according to the sequence numbers.

- 1.Set the model at the position of the sheet material.

- 2.Adjust the size of the model

- 3.Click and paste

|

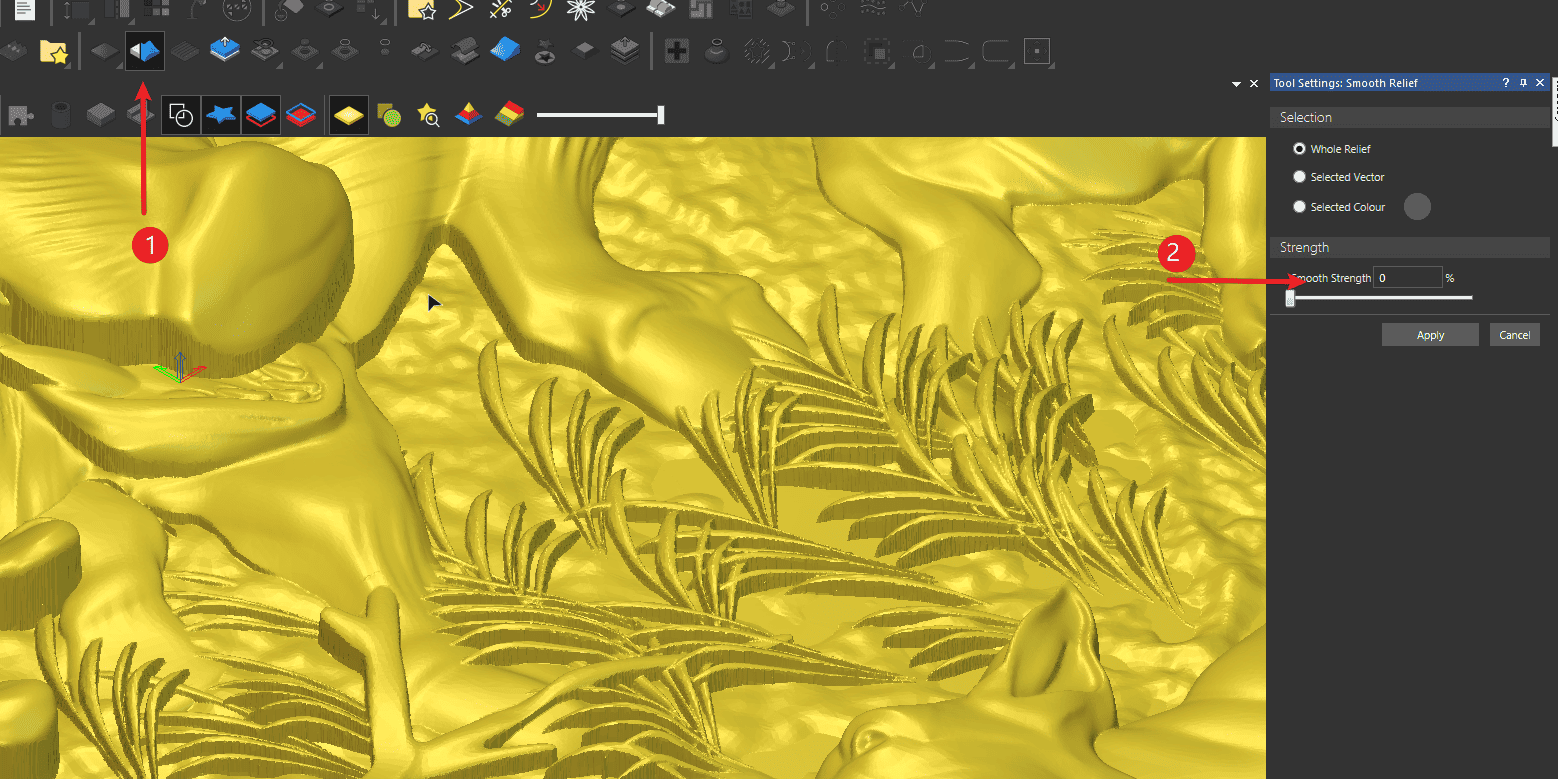

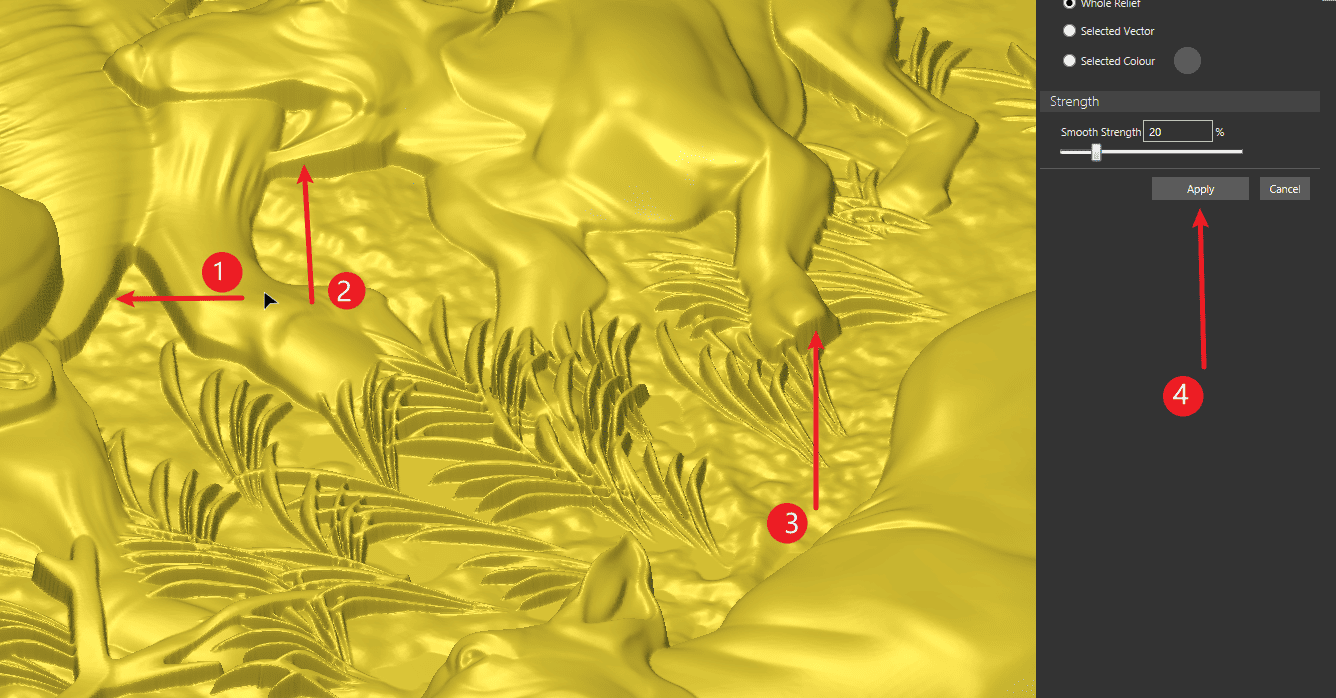

Step 4

Perform the operations according to the sequence numbers.

- 1.Click on the smooth relief texture

- 2.Adjust the degree of smoothness

|

Step 5

Perform the operations according to the sequence numbers.

- 1-3.Check if the edges of the relief height are smooth

- 4.Click to apply.

|

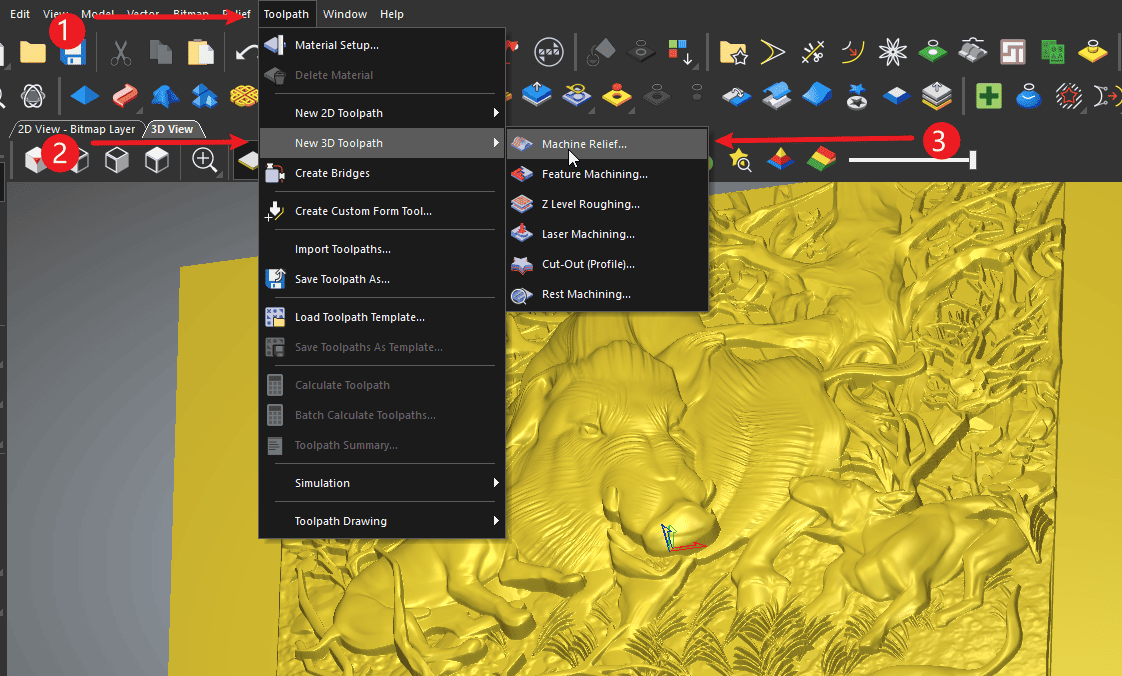

Step 6

Perform the operations according to the sequence numbers

- 1.Click path

- 2.Click on the 3D path

- 3.Click on the relief sword path

|

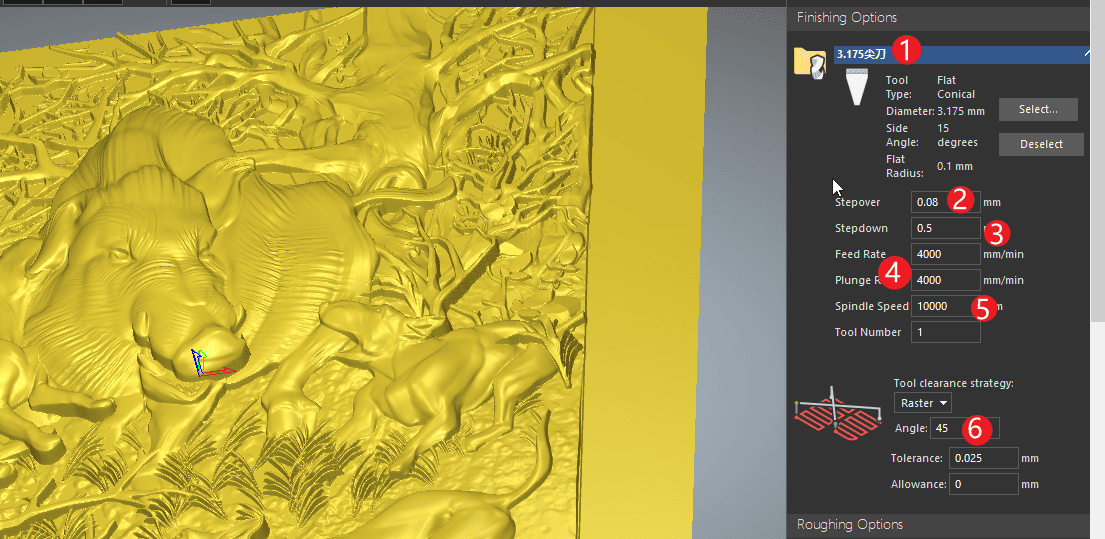

Step 7

Perform the operations according to the sequence numbers.

- 1.Click to add finely processed cutting tools

- 2.Set the distance between each row of the fine processing tool path

- 3.Set the clearance for fine processing removal

- 4.Set the feed speed and the retraction speed (note that here you need to convert according to the maximum speed of the existing machine. Generally, 80% should be used. Do not directly input as shown in the diagram.)

- 5.Set the spindle speed

- 6.Set the angle for the fine processing movement

|

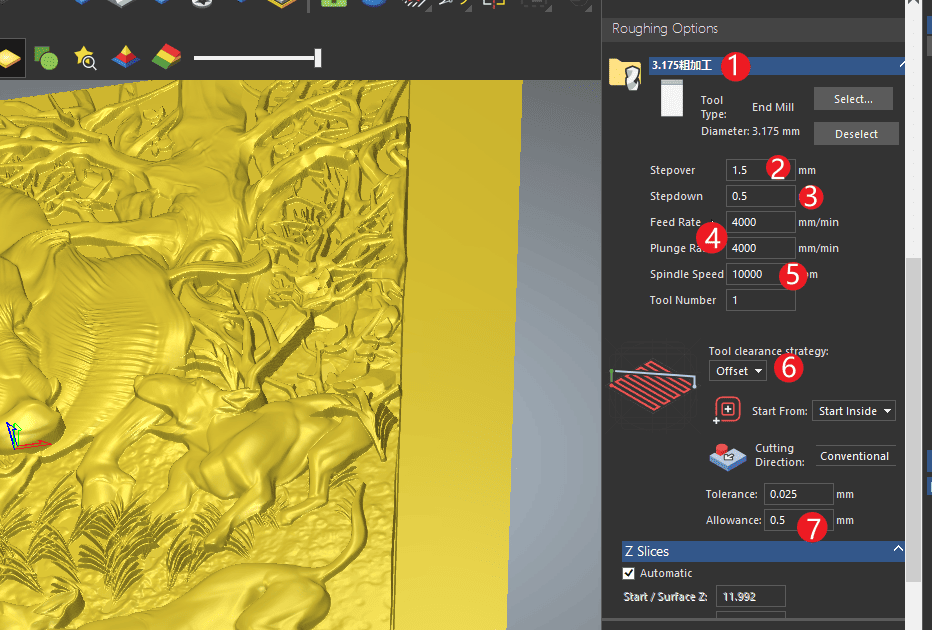

Step 8

Perform the operations according to the sequence numbers.

- 1.Click to add rough-cutting tools

- 2.Set the distance between each row of the rough machining path

- 3.Set the depth of each cut for rough processing

- 4.Set the feed speed and the retraction speed (note that here you need to convert according to the maximum speed of the existing machine. Generally, 80% should be used. Do not directly input as shown in the diagram.)

- 5.Set the spindle speed

- 6.Select the movement mode of the cutting path

- 7.Choose to leave a 0.5 margin for the finishing process.

|

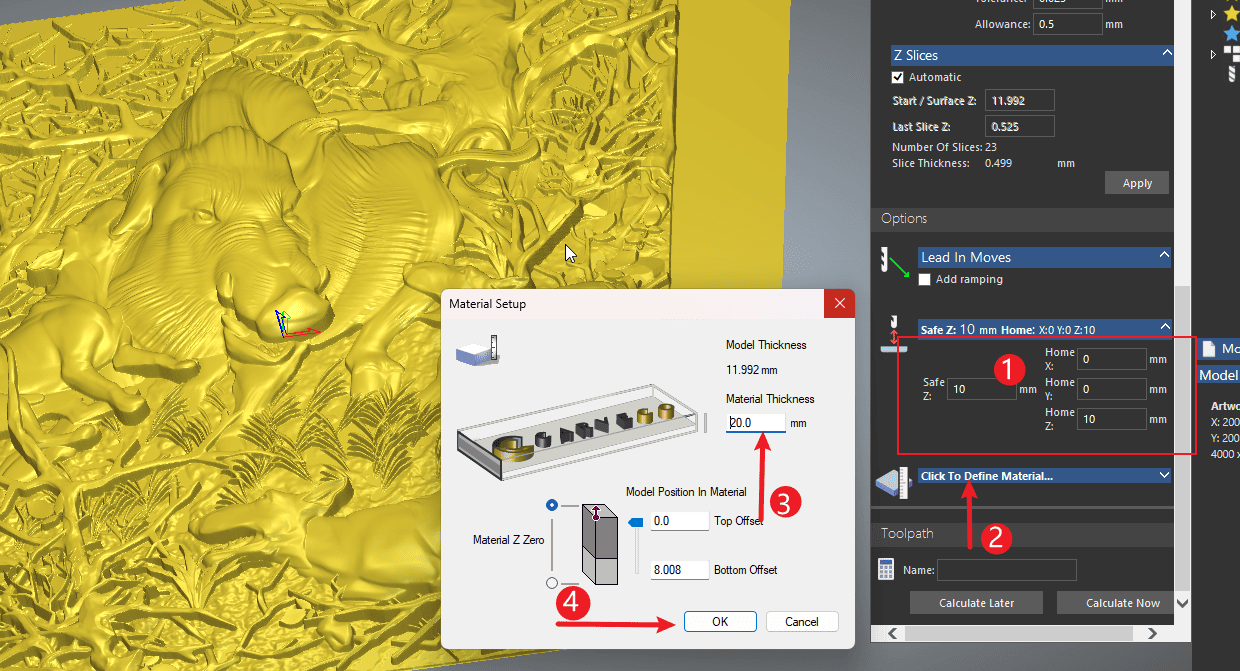

Step 9

Perform the operations according to the sequence numbers.

- 1.Set the safe height of Z

- 2.Click on “Material Settings”

- 3.The thickness of the used materials

- 4.Click “OK”

|

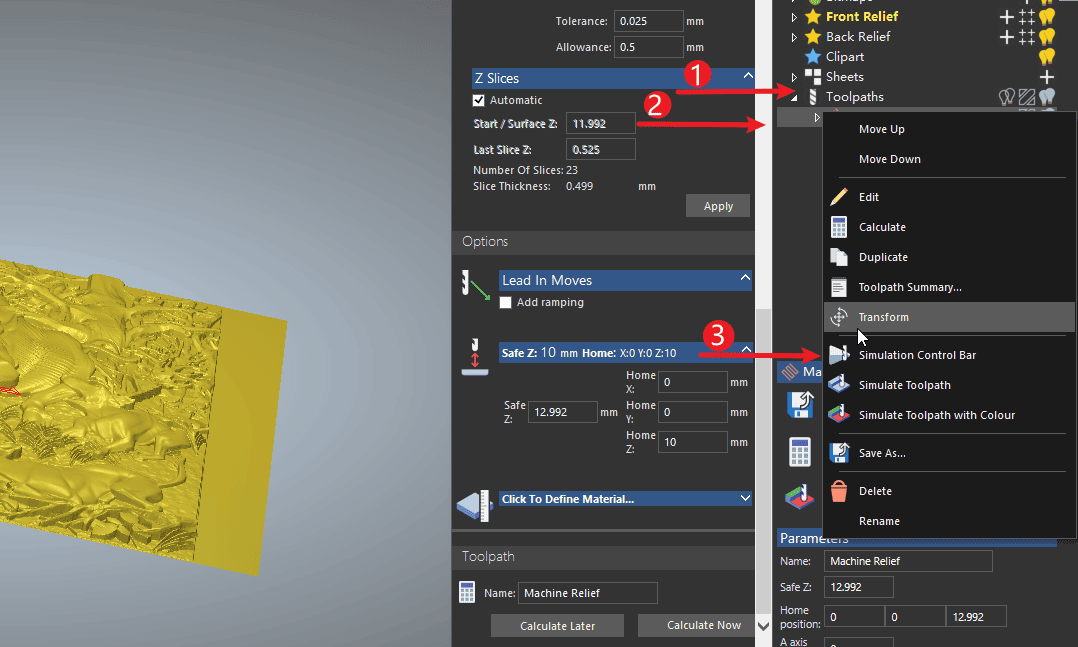

Step 10

- 1.Click path

- 2.Right-click tool path

- 3.Click simulation

|

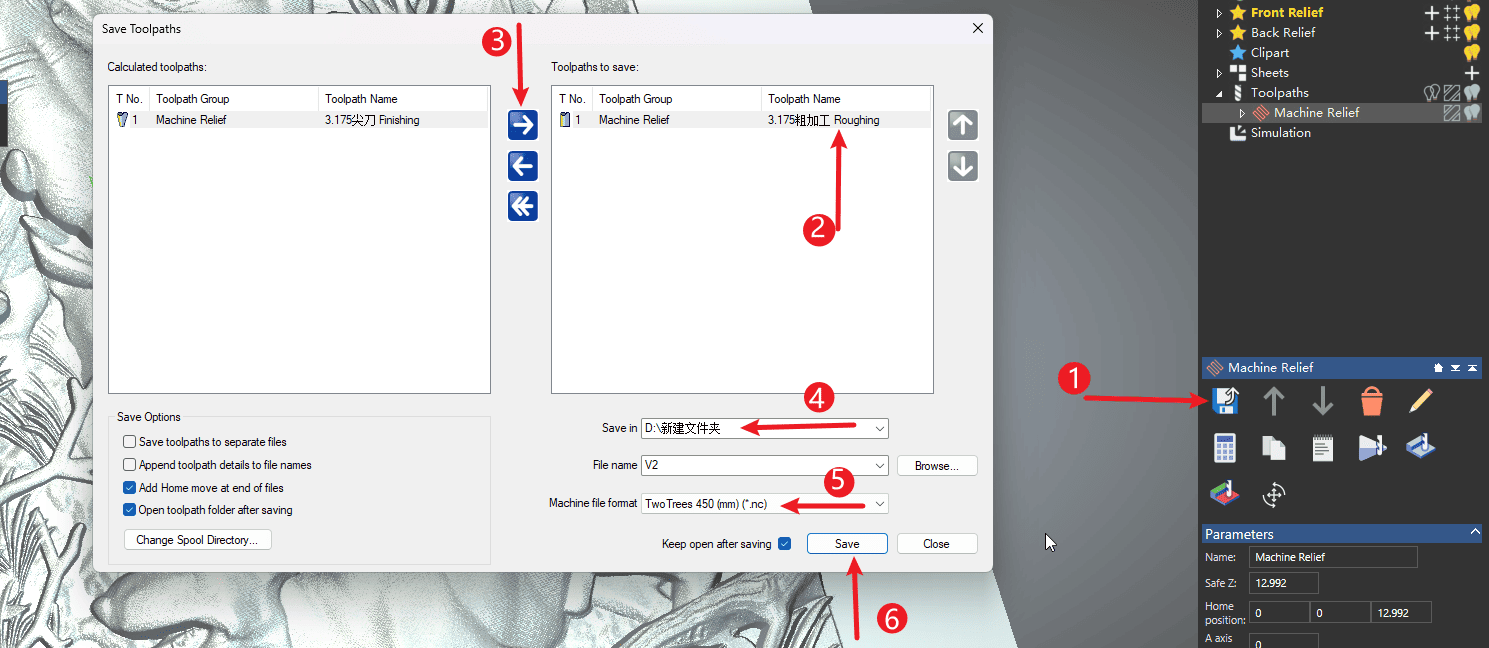

Step 1

- 1.Click to save the cutting path

- 2.Select the export path

- 3.After saving one path, switch to another tool path save (for engraving, the file needs to be saved as two nc files)

- 4.Select the export folder

- 5.Select the post-processing program (this post-processing is applicable to all Twotrees machines)

- 6.Just click “Save” to proceed.

|