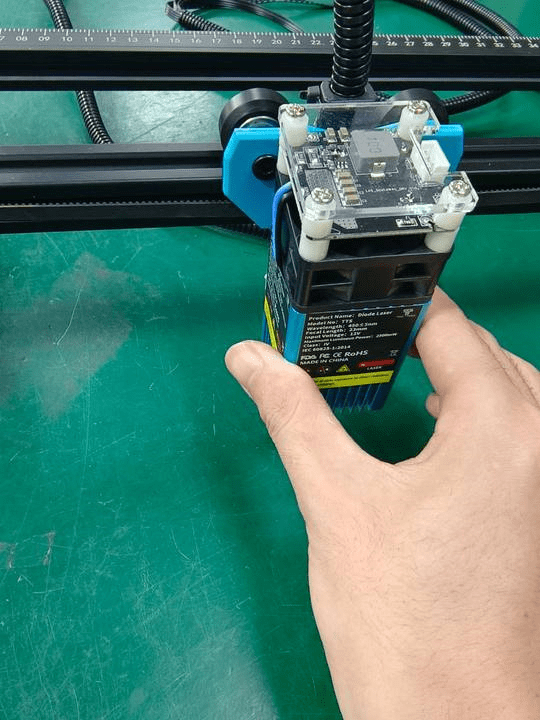

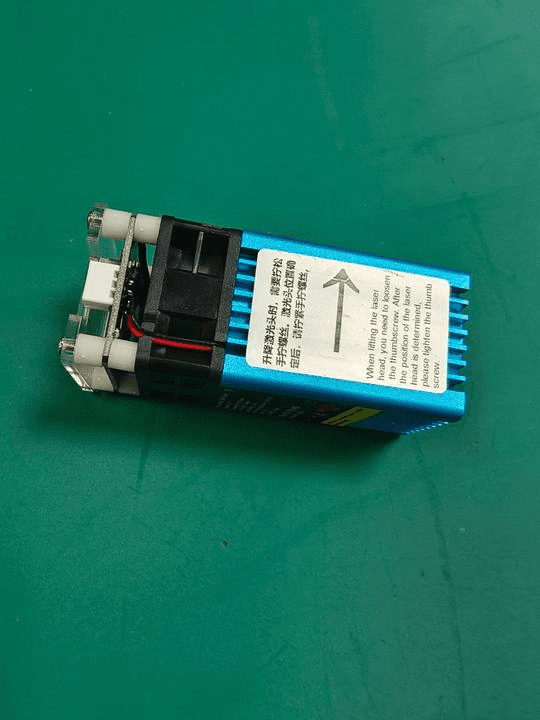

¶ Laser head lens

Laser head lens cleaning steps:

- Disconnect the power supply::

- Before starting the cleaning, the power supply of the machine must be disconnected to ensure that the operation is carried out in the state of no power to ensure safety.

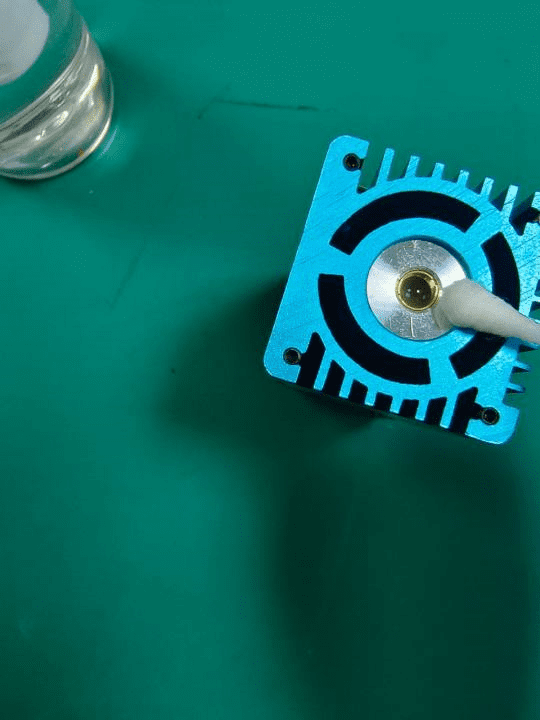

- Use the appropriate cleaning agent:

- Gently wipe the laser lens with alcohol or other recommended cleaning liquid.

- Wipe lenses:

- Gently wipe the lens with a clean cotton swab or special lens cleaning paper to remove dust and dirt.

- Wait to dry:

- After wiping, wait until the lens is completely dry before restarting the machine.

- Avoid liquid infiltration:

- During the cleaning process, be careful not to let the liquid penetrate into other parts of the laser head to avoid damage.

Attachment link description:

- The attachment links may show different types of laser heads, but the wiping process and precautions are universal.

- Ignore the differences in the laser head models in the links and focus on the steps of the cleaning process.

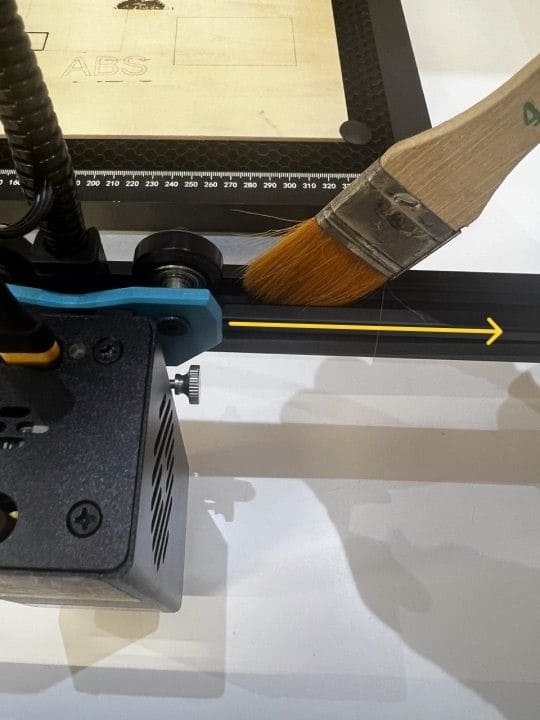

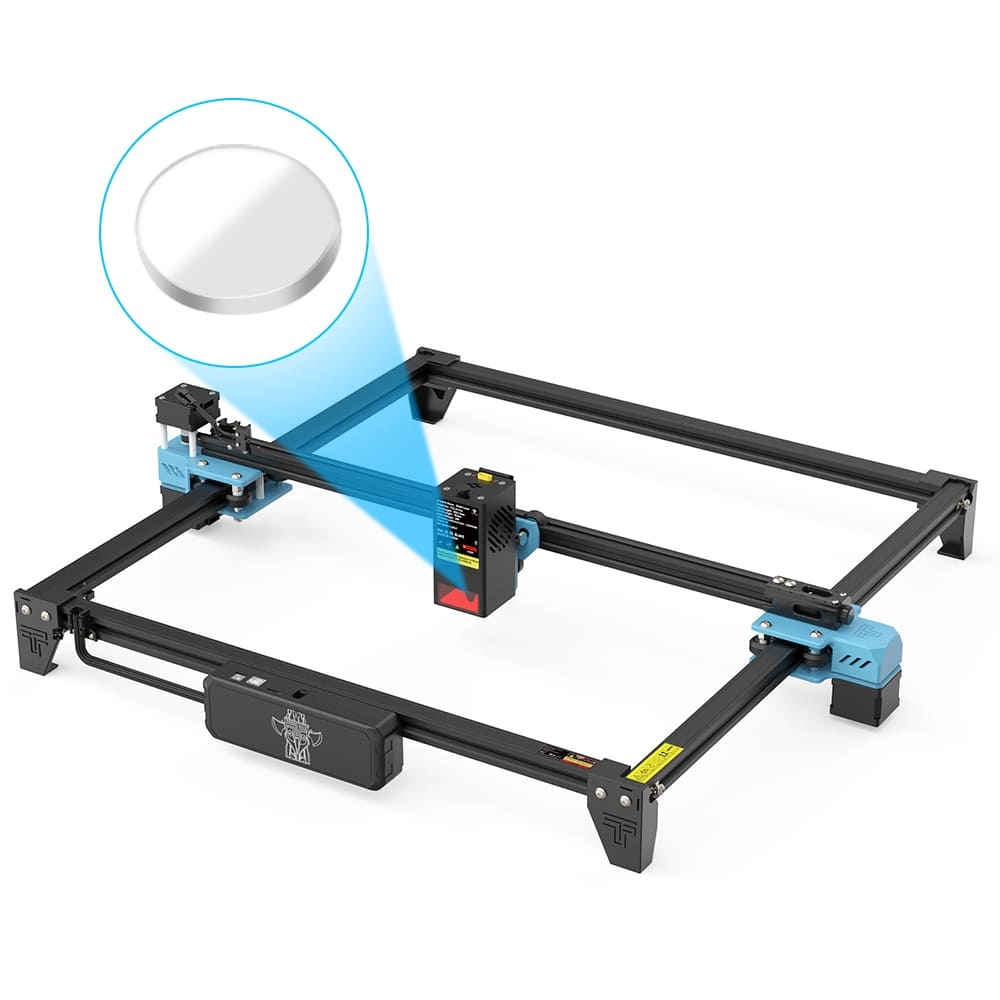

¶ Machine guide

Guide rail cleaning and maintenance steps:

-

Check and clean regularly:

- In order to ensure the smooth operation of the machine, it is recommended to clean the guide rail at least once every two months.

-

Remove impurities from the rail:

- Use a brush to gently remove fine debris and impurities from the rail along the track of the wheel.

-

Cleaning pulley:

- Also use a brush to clean the fine debris on the pulley to ensure that the surface of the pulley is clean and the rotation is smooth.

-

Use compressed air:

- If there is debris or dust that is difficult to remove with a brush, a can of compressed air can be used to blow against the impurities to remove impurities from the guide rail and pulley.

-

Check guide lubrication:

- After cleaning, check the lubrication of the guide rail, and re-apply the appropriate amount of lubricating oil if necessary.

-

Test machine operation:

- After cleaning and maintenance, perform a test run of the machine to ensure that there are no stalling or missing steps.