A laser engraving machine is designed for engraving various materials including wood, plastic, paper, leather, bamboo, foam paper, aluminum oxide, stainless steel, Shuff board, acrylic, and more. It can be used to create personalized gifts, intricate artworks, unique home decorations, and detailed brand products for businesses. Additionally, it aids in fashion design by creating designs on leather and fabric.

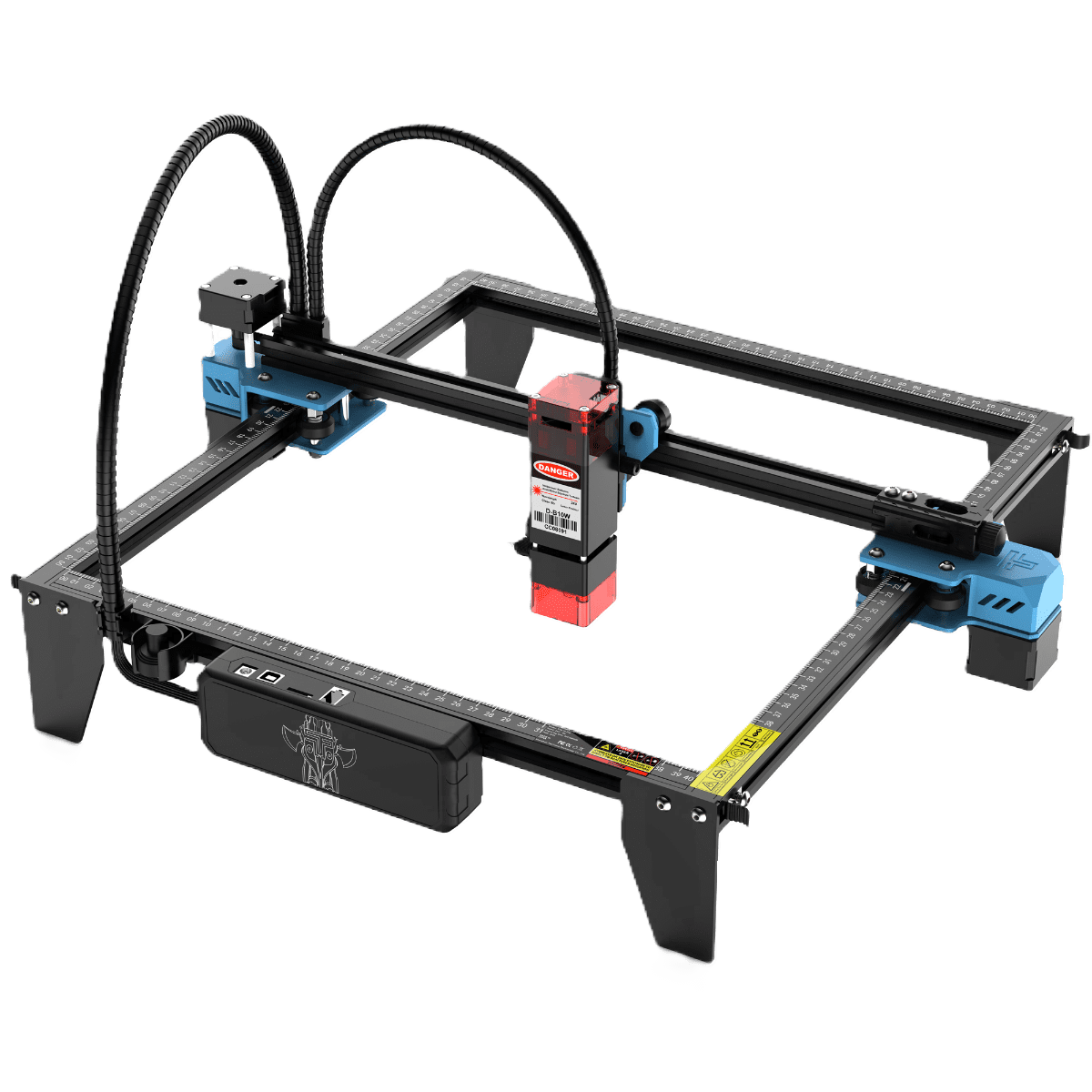

¶ Introduction to the main components

TTS-10Pro works as follows?

It utilizes stepper motors to drive belts, which in turn move the laser head. Engraving or cutting functions are achieved through the movement of the laser head and the emission of light. TTS-10Pro requires software control, mechanical transmission, and a laser light source to operate. The software serves as a vital interface for human-machine interaction, allowing users to edit images and text, adjust parameters, and start/stop operations. The engraving speed of TTS-10Pro is extremely fast while maintaining high precision.

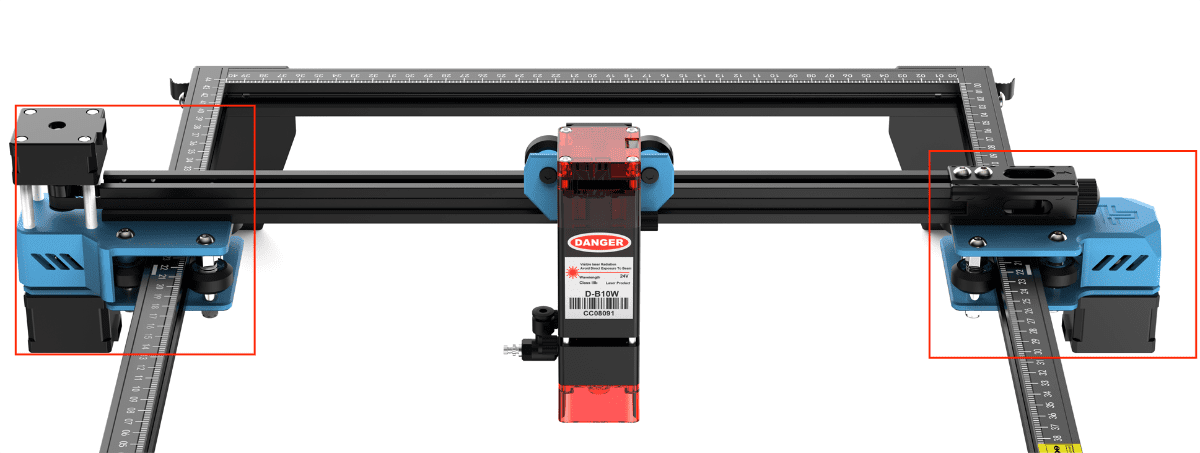

¶ The left and right components

The left and right components consist primarily of motors, synchronous belts, and rails. The Y-axis is driven by two 42 stepper motors, while the X-axis is driven by a single 42 stepper motor. These components are essential parts of the TTS-10Pro for movement during operation.

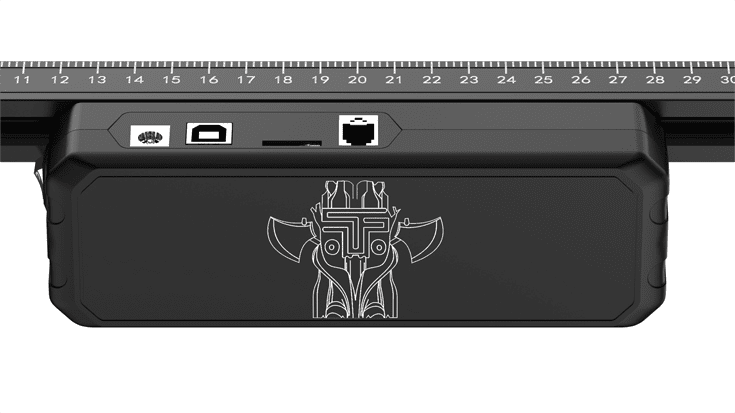

¶ The mainboard component

The TTS-10Pro utilizes the high-performance MKS LS ESP32 PRO V2.1 laser engraving machine mainboard. The LS ESP32 PRO V2.1 mainboard is a solution specially developed for desktop engraving machines. It features the ESP32 dual-core 32-bit super CPU, with a main frequency of up to 240MHz, ensuring excellent performance.

Equipped with noiseless TMC22 drivers, this mainboard can achieve a maximum operating speed of 30000mm/min, providing high efficiency while maintaining a quiet working environment. The LS ESP32 PRO V2.1 mainboard boasts high-performance characteristics.

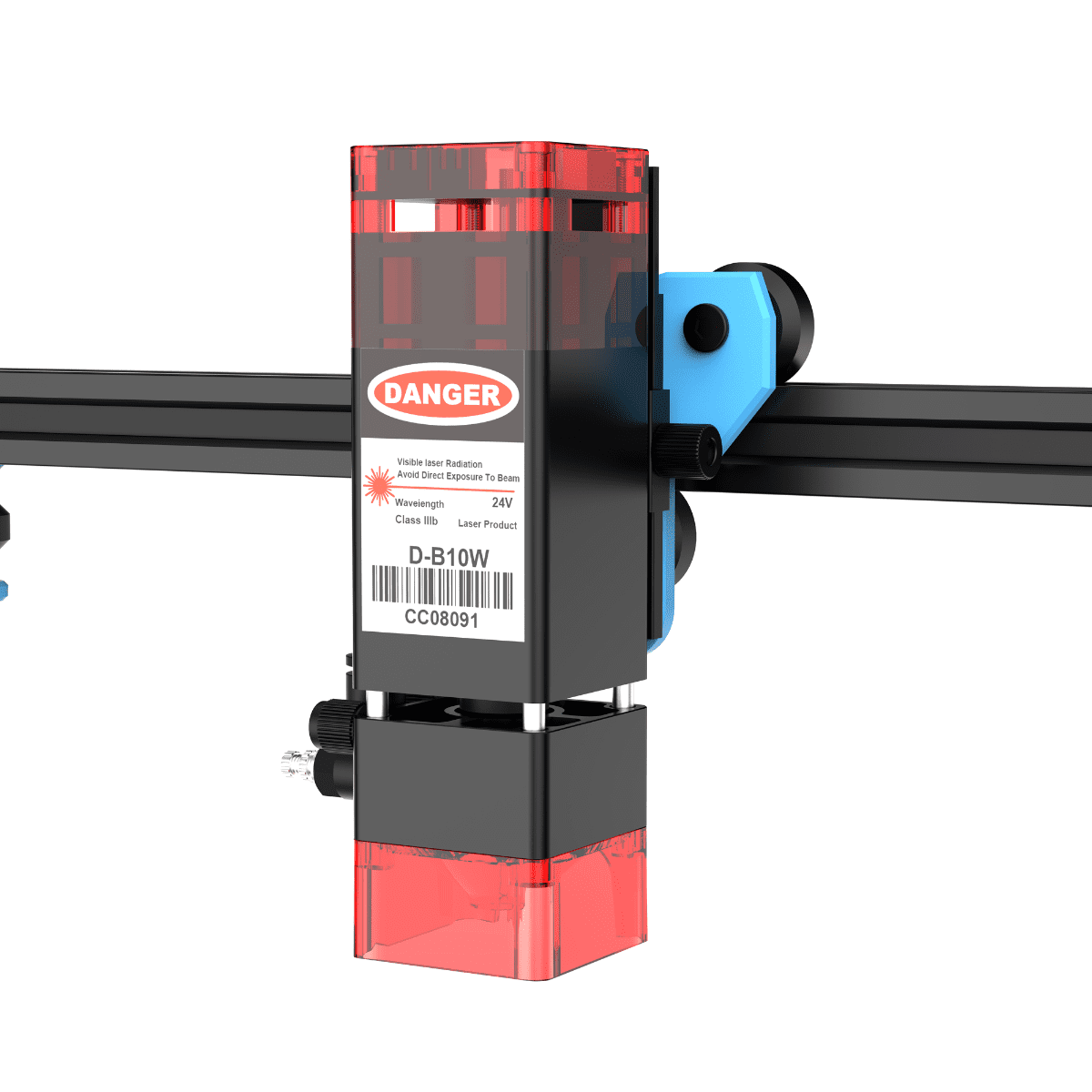

¶ The laser head component

The TTS-10Pro engraving machine utilizes a high-power 10W laser module, with a small spot size that presents a nearly rectangular shape. This configuration concentrates the light source energy more effectively, extending the effective energy range and increasing energy density. As a result, it offers stronger cutting and engraving capabilities compared to a 5W laser module.