¶ TS2 Series Introduction

Laser engraving machines are designed for engraving a variety of materials including wood, plastic, paper, leather, bamboo, sponge paper, aluminum oxide, stainless steel, snowboard, acrylic, and more. They are used for creating personalized gifts, intricate works of art, and unique home decorations. Additionally, they aid in the production of detailed branded products for businesses and create fashion designs on leather and fabric.

¶ Currently, the TS2 series offers three models (with some differences in appearance and color), here are the machine introductions:

¶ Introduction to Key Components

¶ How does TS2 work?

The TS2 features a large engraving area of 450mm * 450mm and employs a fully modular design, which provides robust module expansion capabilities. The machine is equipped with a gyroscope sensor that, when tilted more than 15° (tilted, flipped, or dropped), will trigger the gyroscope, causing the laser to automatically stop working, enhancing the safety of machine usage.

|

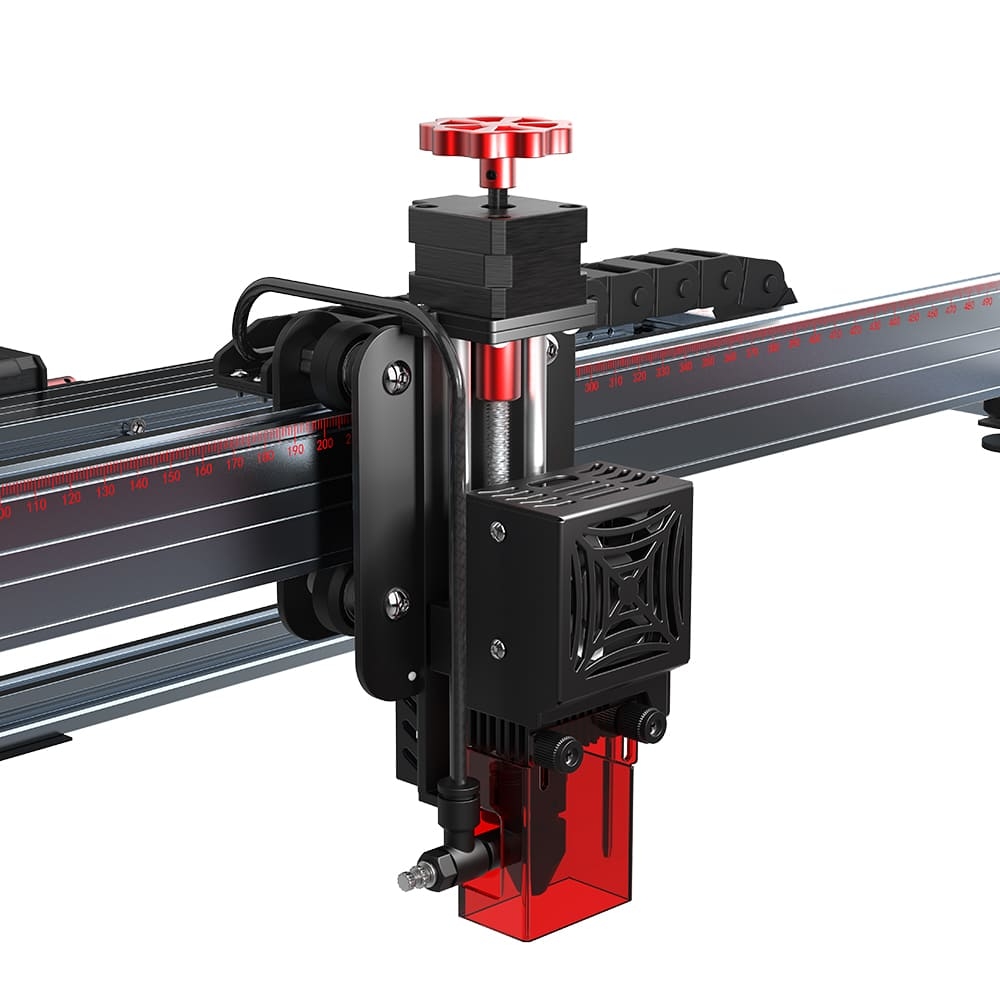

¶ Laser Head Component

¶ The TS2-10 and TS2-20W laser engravers use high-power laser modules, which have a very small spot size with a nearly rectangular shape. The light source is more concentrated, providing a longer effective energy range, higher energy density, and better engraving results. The cutting capability is significantly enhanced. They also feature an automatic focus calibration function, eliminating the need for manual focusing, making the process more convenient.

¶ TS2-40W Laser Head

The TS2-40W laser head also features a nearly rectangular spot, allowing it to cut through thicker materials and process a more diverse range of materials. The TS2-40W laser engraver uses manual focusing. There is an adjustable slider on the laser head for direct and precise adjustment of the focal distance, ensuring the correct engraving distance.

|

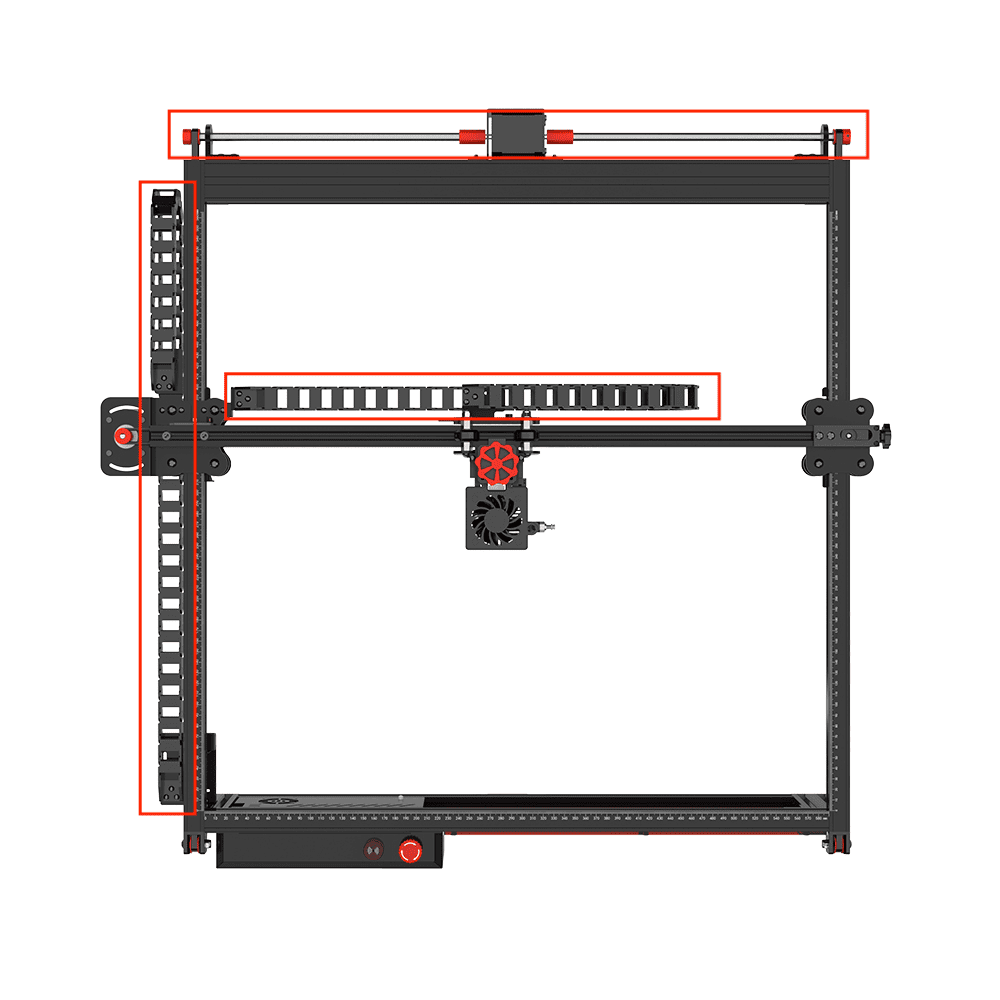

¶ Y-Axis Transmission and Drag Chain Components

The Y-axis transmission primarily relies on a motor to drive two pairs of light rods, which in turn drive the synchronous wheel and belt. This method of transmission has the advantages of simple structure and powerful functionality.

Both the X-axis and Y-axis are equipped with drag chains. These chains not only assist in the movement of the X and Y axes but also encase the wiring, resulting in a neater appearance and smoother movement.

|

¶ Wireless Transmission Feature

The MKS DLC32 motherboard kit is a standalone carving control board specifically developed for desktop engraving machines. It features a 32-bit high-speed ESP32 module with integrated WIFI capabilities, enabling rapid engraving and control via a mobile app. The MKS DLC32 is compatible with the installation holes and circuit board dimensions of the MKS DLC and can also be used in conjunction with GRBLaser and LightBurn PC software.

|