¶ Introduction

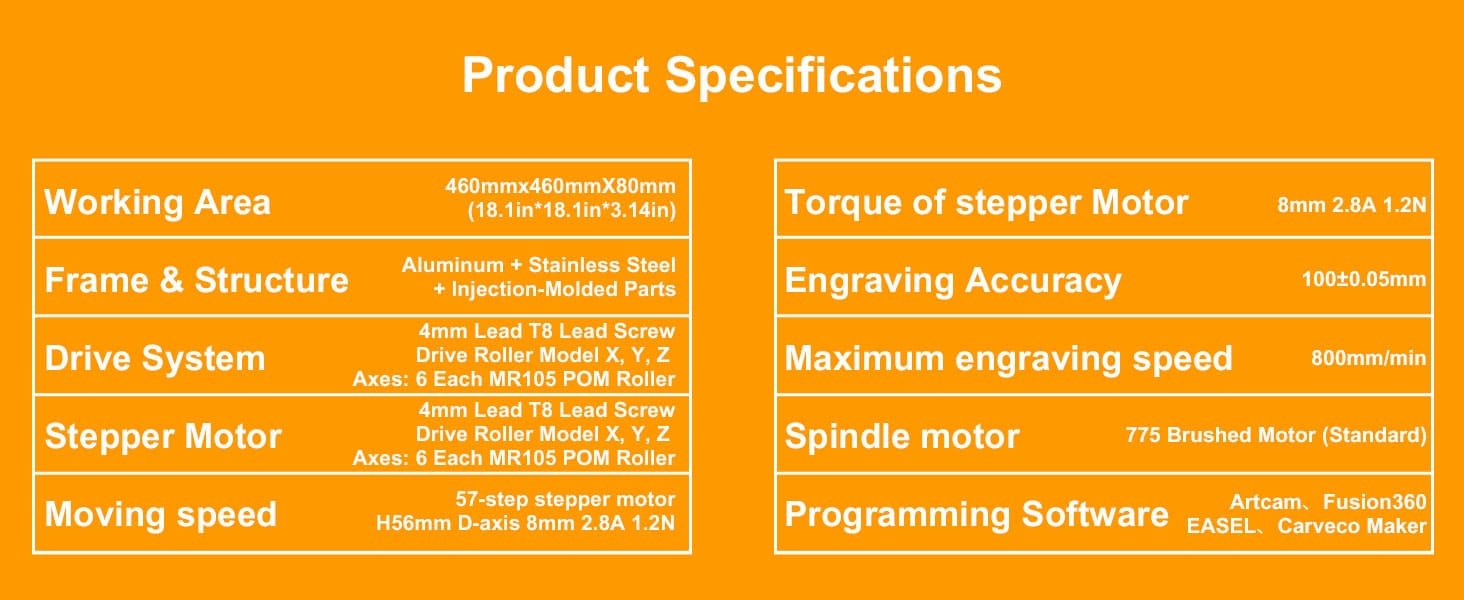

The TTC450Pro (25) engraving machine is an upgraded version of the original model with an enhanced control system. Its more user-friendly structural design significantly improves the ease of installation.

|

¶ control system

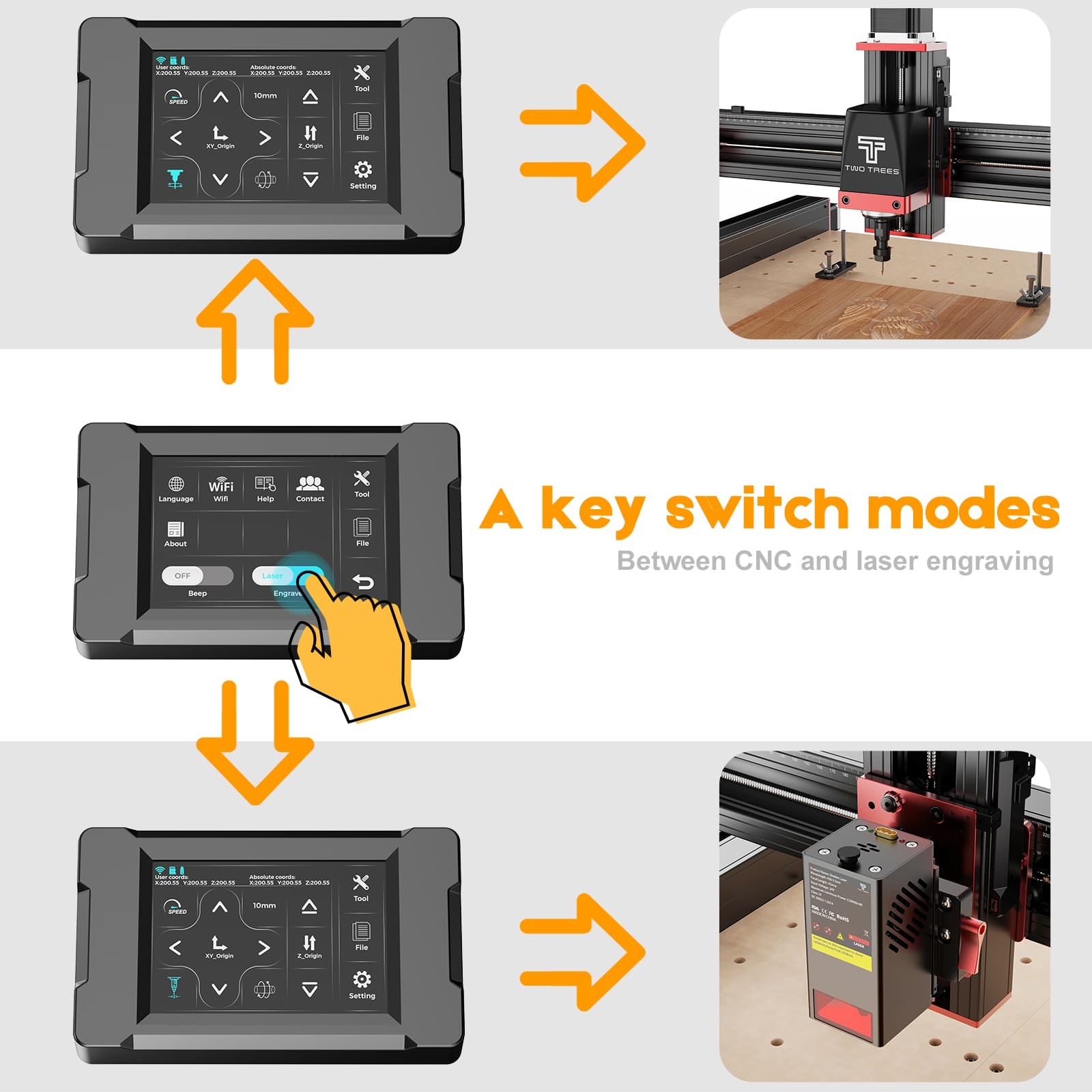

The control system is the core part for the interaction between the engraving machine and the user. It directly affects the convenience and efficiency of the operation. A simple and efficient control system not only enables users to quickly master the operation methods, but also significantly improves work efficiency. Users only need to complete the programming of the file on the computer, then easily import it into the engraving machine, and can start the engraving process with just one click, without worrying about the complexity of technical operations.

|

¶ Mechanical structure

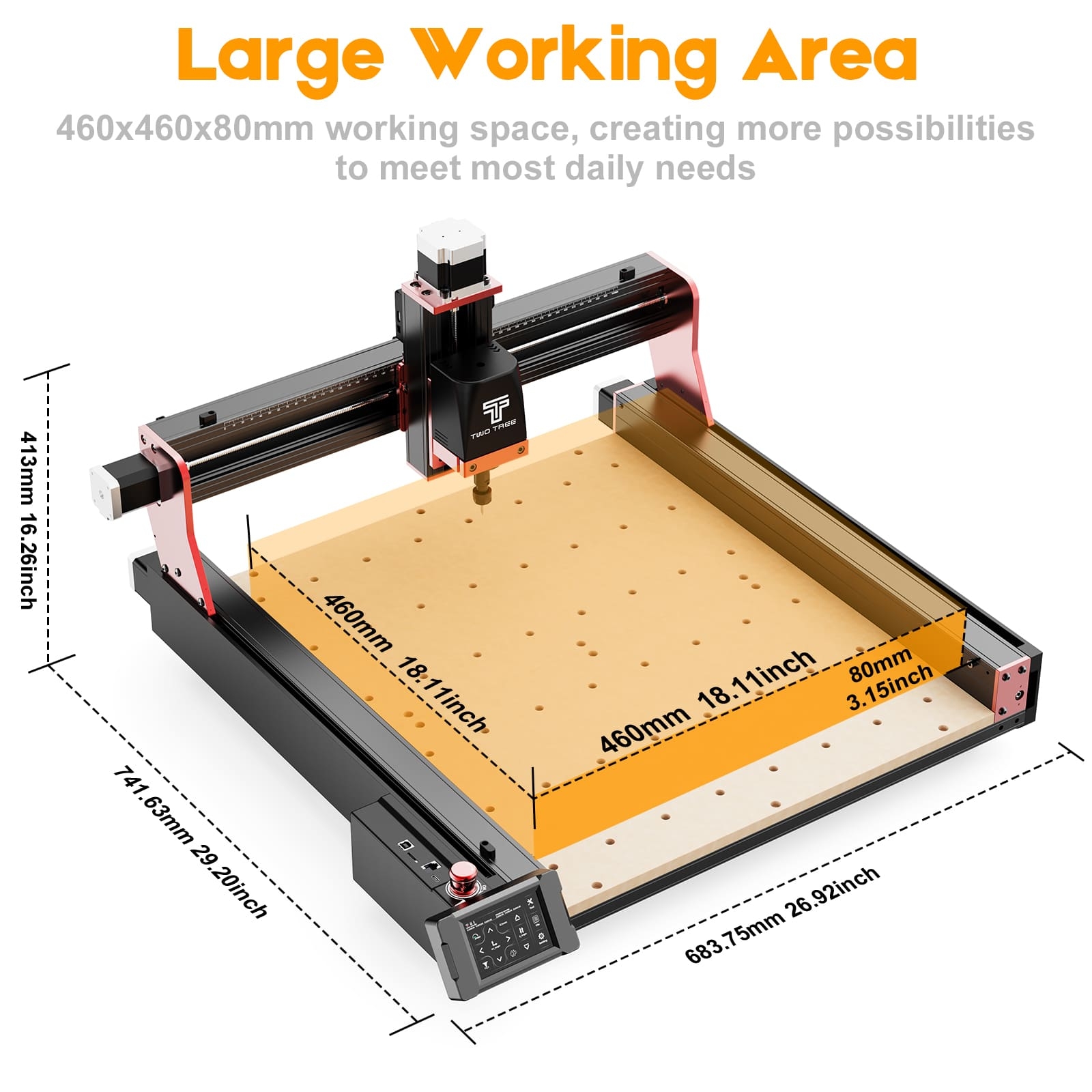

An outstanding mechanical structure is a key factor in ensuring the accuracy of a CNC machine. The TTC450ro CNC machine performs particularly well in this regard. Its three-axis system features high-precision lead screws and anti-friction nuts, effectively eliminating mechanical stress during movement. This design not only enhances the stability of the machine but also ensures smoothness and consistency during high-precision operations. Whether it is fine line engraving or complex three-dimensional model processing, the TTC450Pro can meet the most stringent process requirements with outstanding accuracy and reliability.

¶ Carving tools

The choice of carving tools is also very important. Different carving tools can meet different work requirements. The TTC450Pro not only can use the standard spindle, but also can be adapted to different work requirements by replacing it with a 500W spindle, trimming machine, laser engraving head, etc.

|

¶ Electrical section

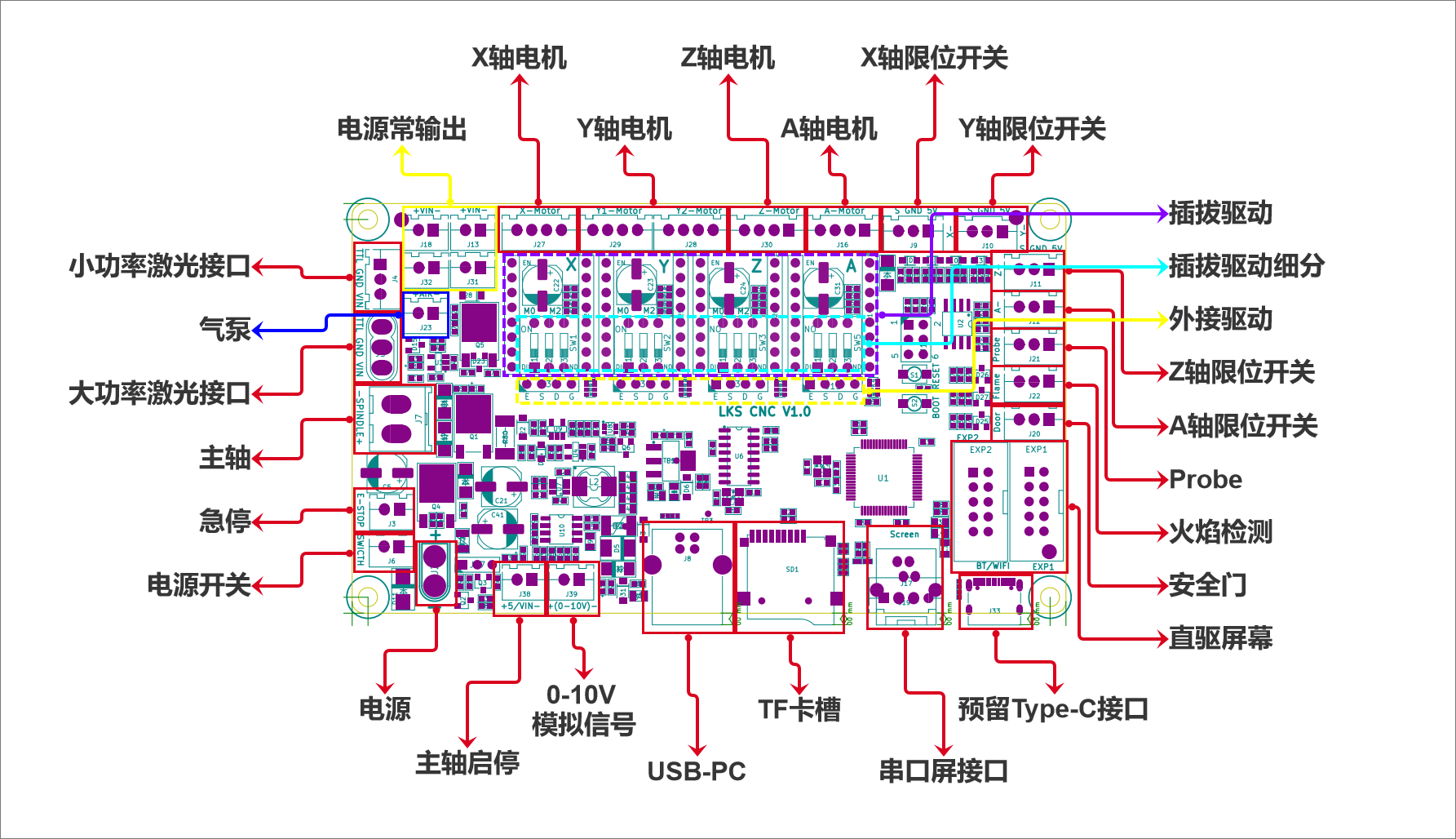

The main control board is the most crucial part of the engraving machine. It is responsible for coordinating and managing all the operations and functions of the machine. The stability, accuracy and reliability of the engraving machine largely depend on the performance of the main control board. A high-performance main control board can ensure the smoothness and efficiency of the machine when performing complex tasks.

|

¶ Reference Document

|