¶ Machine Cannot Connect to Computer, How to Handle?

- Ensure that the machine is turned on.

- Make sure the USB cable is connected to the machine’s port.

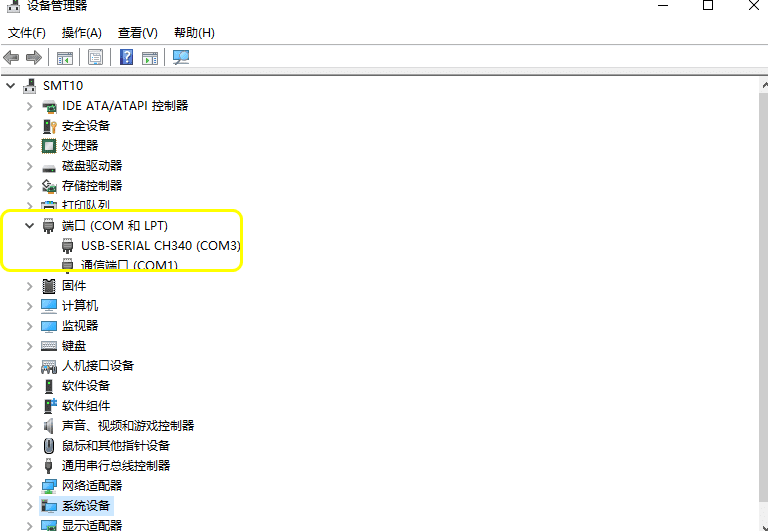

- Check if the computer can recognize the machine’s COM signal. (Or try inserting it into a different port on the computer)

- If no new COM is seen in the previous step, it is necessary to install a CH340 driver. It can be obtained from the TF card files. Alternatively, install the CH340 driver through the lasergrbl tools.

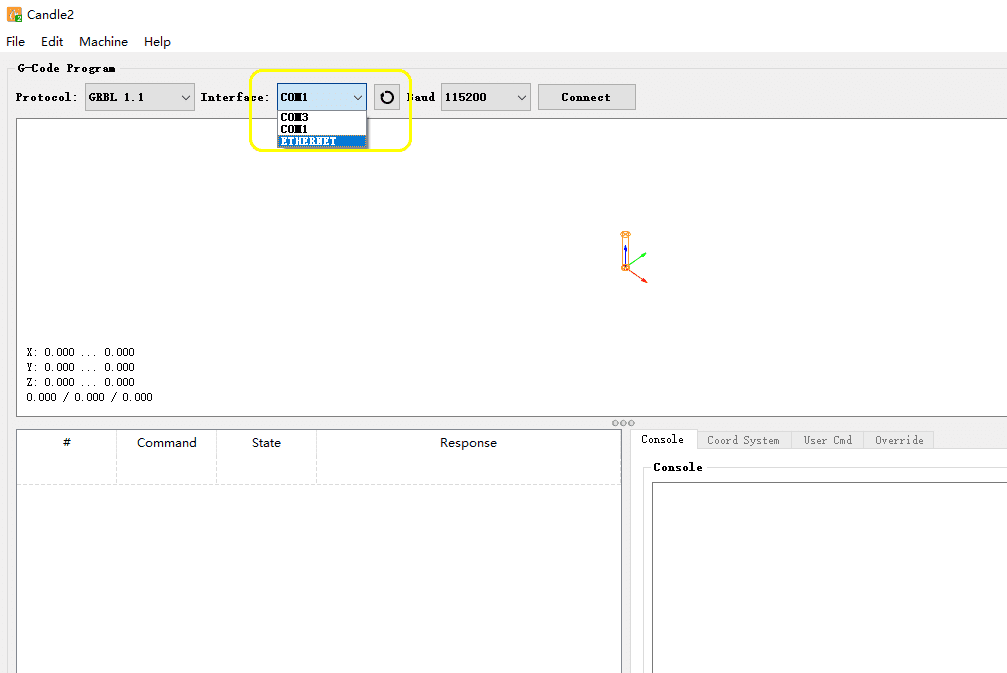

- Set the correct baud rate, 115200;

- Select the correct “COM” port in the software. (You can try every COM port)

- Click to connect.

- If the above steps still cannot connect, please restart your computer and then re-execute steps 5-7. (There may be software conflicts)

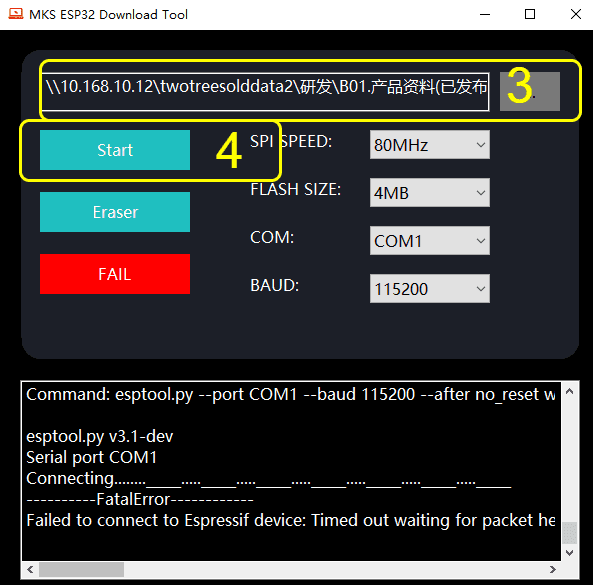

- If it still fails and there is a prompt message in the left dialog box of the software, you need to update the firmware. Then redo the above steps.

- If you cannot connect and control the machine with candle, but you can with easle or GRBL and other software, it indicates that there is a problem with the candle installation package. Please completely uninstall and go to the candle official website to download and reinstall.

¶ Motor Does Not Work, How to Handle?

- Ensure that the machine has successfully connected to the computer’s Candle software. If it does not connect successfully, you cannot control the motor to operate.

- Check if the motor cables are installed correctly. If in doubt, try re-installing them.

- If some of the motors work normally, open the control box, find the main control board, and try to swap the motor cables inside the control box. If they still do not work after swapping, it may be that the cables have problems, please inform us for replacement.

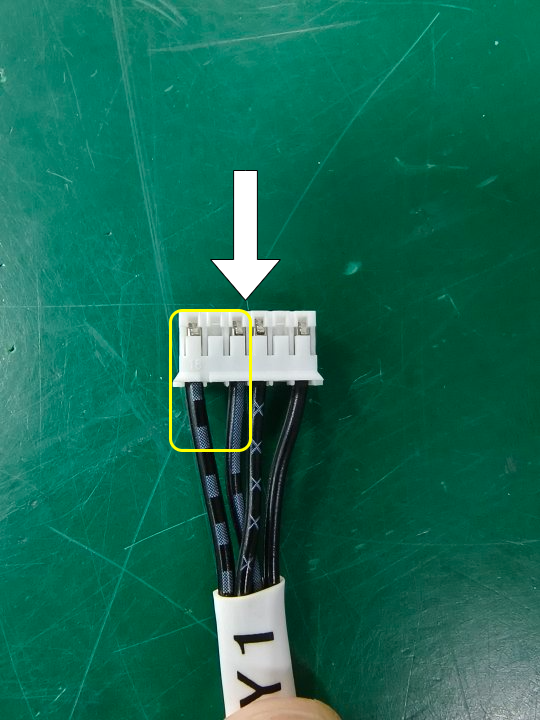

- If the motor vibrates but does not move, it may be that the cable sequence is problematic. You can use a tool with a sharp corner to swap the order of the two central wires.

- After swapping the cable order, if the direction is incorrect, you can try swapping the order of the two adjacent wires on the left.

- If after the above steps, the originally normal motor also does not work, it may be that the driver of the main control board is damaged. Please inform us for replacement. When informing, providing a video will help us confirm the problem and replace the new parts.

|

¶ Machine Makes Unusual Noises, How to Handle?

May be caused by the following two situations:

-

Exceeding the machine’s working travel.

Please try the following operations: Set the software parameters according to the machine’s nominal working size. The working range of TTC450 is 460mm * 460mm * 80mm. -

Transmission parts friction, please try the following operations:

- Turn off the machine power, manually move the X-axis left and right, move the Y-axis front and back, check for any jamming or difficulty in movement.

- Test each drive part separately, including checking the drive voltage (the voltage should be around 0.96V).

- Adjust the screws or add lubricant according to the situation of different parts to reduce friction.

¶ Machine Cannot Start, How to Handle?

- Make sure the adapter or power cord is connected to the power source and observe whether the indicator light is on.

- Press the switch repeatedly, observe if there are any changes in the machine.

- Remove the TF memory card, then restart the machine.

- Unplug all the motor cables to disconnect them, then restart the machine. If the machine can start, plug the cables back in one by one. When the machine shuts down again, it may be that the plugged cable has a problem.

- Open the control board box, check if there is any detachment of the switch wire.

- Try using another adapter of the same specification.

¶ Machine Moves Incorrect Distance, How to Handle?

After successfully connecting the software and the machine, please follow these steps:

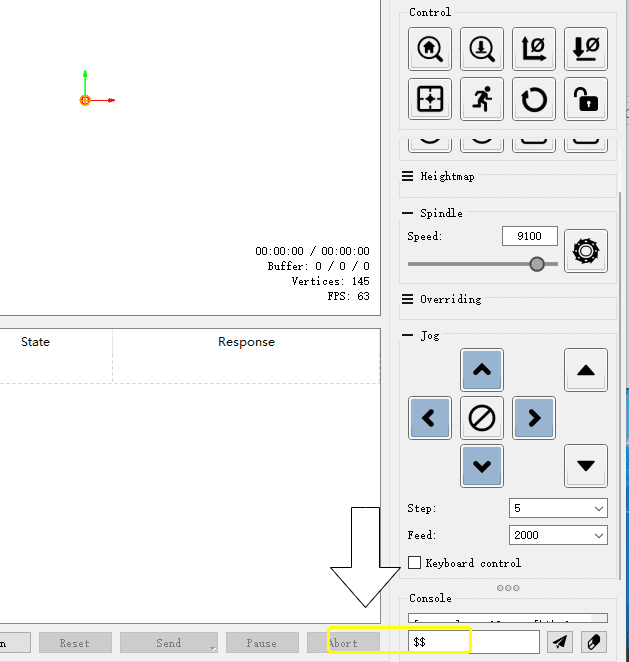

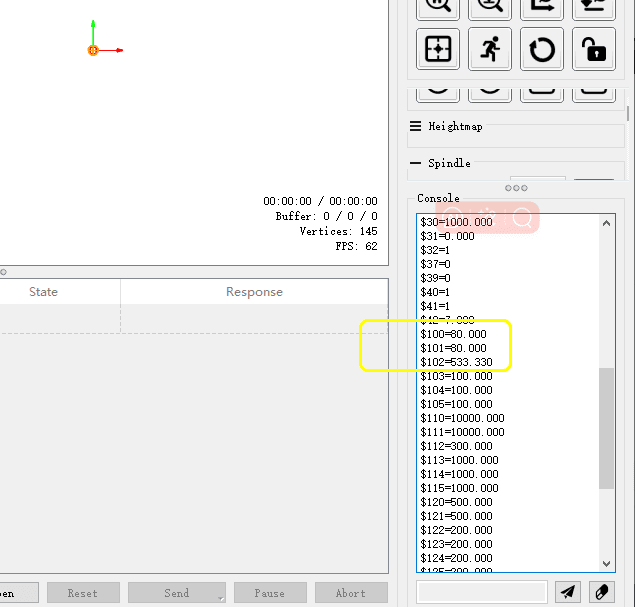

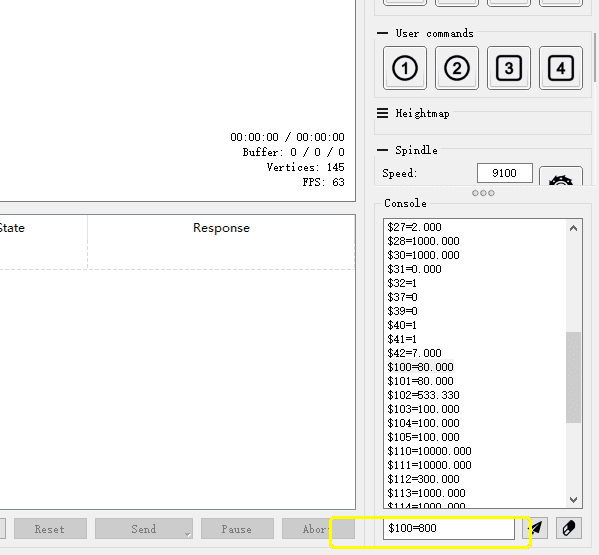

- Enter $$ in the control bar to bring up the parameter page.

- Find the parameters $100, $101, and $102.

- Check if all three values are set to 800.

- If any of the values are not 800, change them to 800.

¶ Machine Axis Moves in the Opposite Direction, How to Handle?

After successfully connecting the software and the machine, please follow these steps:

-

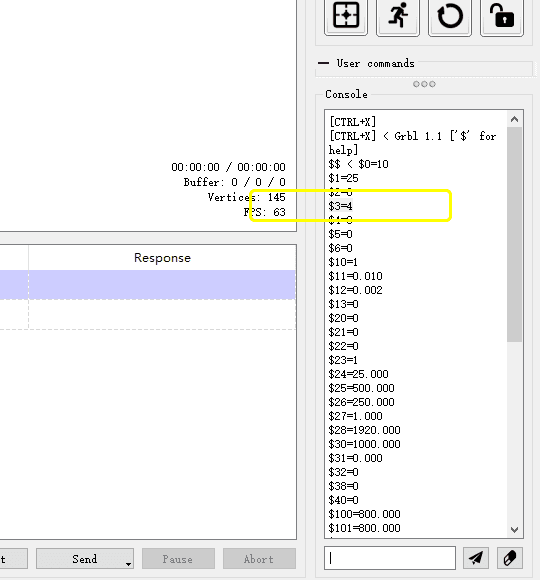

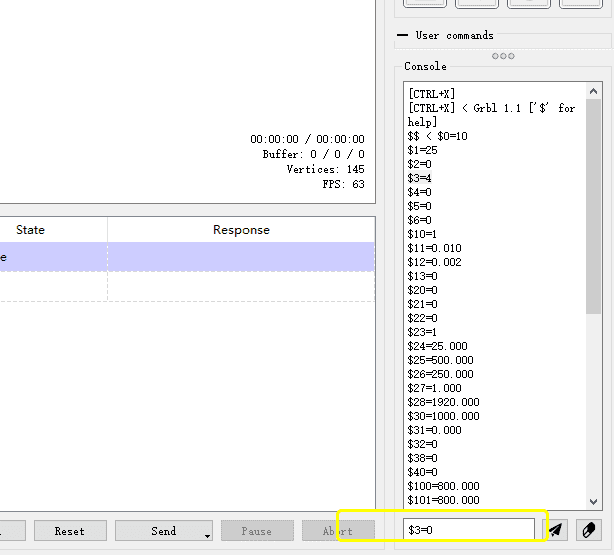

Enter $$ in the control bar to bring up the parameter page.

-

Find the parameter $3.

-

Modify the value of $3 with the following commands:

- $3=0

- $3=1

- $3=2

- $3=3

- $3=4

- $3=5

-

After each modification, check if the direction of each axis is correct.

-

Try up to 6 times until the direction of each axis is correct.

¶ Mainboard Power Switch (Angel Eye Switch) is Ineffective, Machine Cannot Start

-

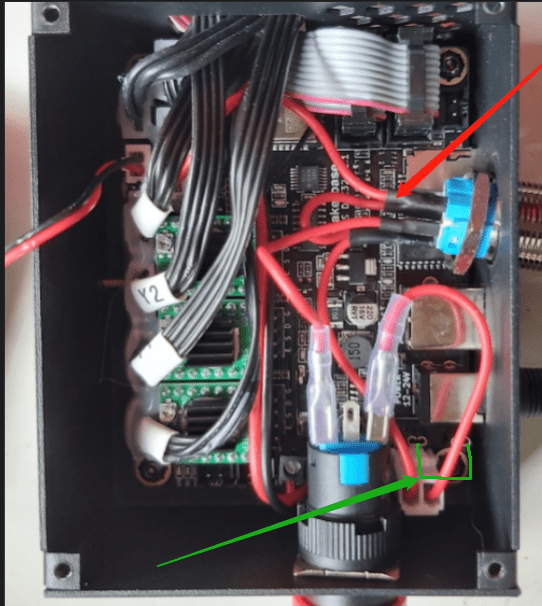

First, disassemble the mainboard control box and carefully check the wiring of the power switch to ensure that the wiring is correctly connected and there is no damage or detachment.

-

Then, try to short-circuit the power interface on the mainboard and try to start the machine. If the machine can start normally, this may indicate that there is a problem with the power switch (Angel Eye switch), which may be damaged.

These two steps can help determine if the power switch is damaged, but if the problem cannot be solved, further inspection or replacement of the power switch may be necessary.

|

¶ Machine Screen Shows Blue Screen (White Screen) and Cannot Operate, How to Solve?

-

Loosen the four screws on the back of the screen, then try to power on again. If the problem returns to normal, consider adding an insulating pad when reinstalling the screws.

-

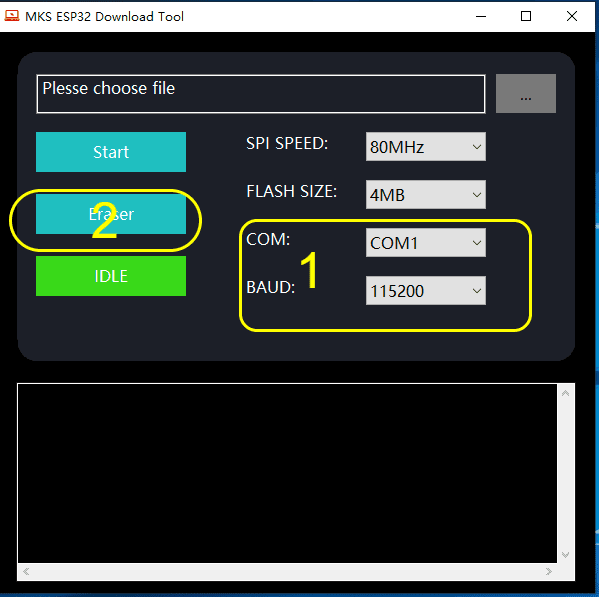

Try to re-flash the firmware for the machine, then power on again. Check if the problem is resolved.

-

If the above methods cannot solve the problem, please contact us, and we will replace a new screen for you.

¶ X-Axis Sheet Metal Parts Shake, Y-Axis Motor Shafts on Both Sides are Loose

-

The sheet metal parts behind the BOM wheel on the back have an eccentric nut installed, which may not have been adjusted properly at first, and may gradually loosen during subsequent use. Therefore, it is necessary to tighten the eccentric nut with a wrench to ensure its stability and normal operation.

-

The motor shafts have springs in the middle, so slight looseness is a normal phenomenon, there is no need to worry too much.

¶ Machine Can Move Normally, But the Carving Appears Blurry and Unclear

There is a brass nut behind the sheet metal parts of the X-axis position, the screws on it may be loose and need to be tightened, see the link for the picture.

¶ Lead Screw Movement Bends and Deforms

-

If you suspect that the lead screw is bent, separate the lead screw from other components and rotate it alone to check for any unevenness or blockages to determine if there is a problem with the lead screw bending.

-

If you suspect that the coupling is deformed, separate the coupling from other components and check its structure and rotation alone to determine if there is a problem with the coupling deformation.

¶ When the Screen Does Not Display

-

Check the Ethernet cable connection: Please make sure the Ethernet cable connection is firm, if you find it loose, please retighten the connection, or try changing the order of the Ethernet cable and restart the machine.

-

Screen line looseness: During the transportation of the machine, vibrations may occur, which may cause the internal wires of the machine to become loose, resulting in poor contact or complete disconnection. When this happens, the screen may display white and cannot work normally. Please first check if there are any issues with the lines.

-

Mainboard or screen failure: If the Ethernet cable connection and screen line looseness issues are ruled out, and the screen still cannot display, it may be that the mainboard or screen has failed. If there are multiple machines of the same model, you can try replacing a normally displayed

screen to the machine with a problem. If the replaced screen can display normally, then the original screen may have a problem; if it still cannot display after replacement, it may be that the mainboard has a problem. If you encounter this situation, please contact the after-sales customer service for further processing.

¶ Mainboard Does Not Read the Card

-

SD card issue:

- First, check if the SD card can be used normally on the computer. If it can, while backing up the files, try to format the SD card.

- Insert the formatted SD card into the mainboard and test it with power on. If the mainboard still cannot recognize the SD card, it indicates that the SD card may have a problem, and it is recommended to replace it with a new one.

-

Check if the card slot is loose:

- Long-term use may cause the card slot to shake, resulting in poor card reading. If you suspect that the card slot is loose, you need to replace it with a new card seat.

- Sometimes the card may suddenly become unresponsive after being inserted for a while. You can try quickly inserting and removing the card a few times, then turn off the power, clean the card slot with alcohol, and insert the card a few more times. If it still cannot be used normally after cleaning, it may be necessary to replace it with a new card seat.