¶ Introduction to Main Components

How does the SP-5V3 work?

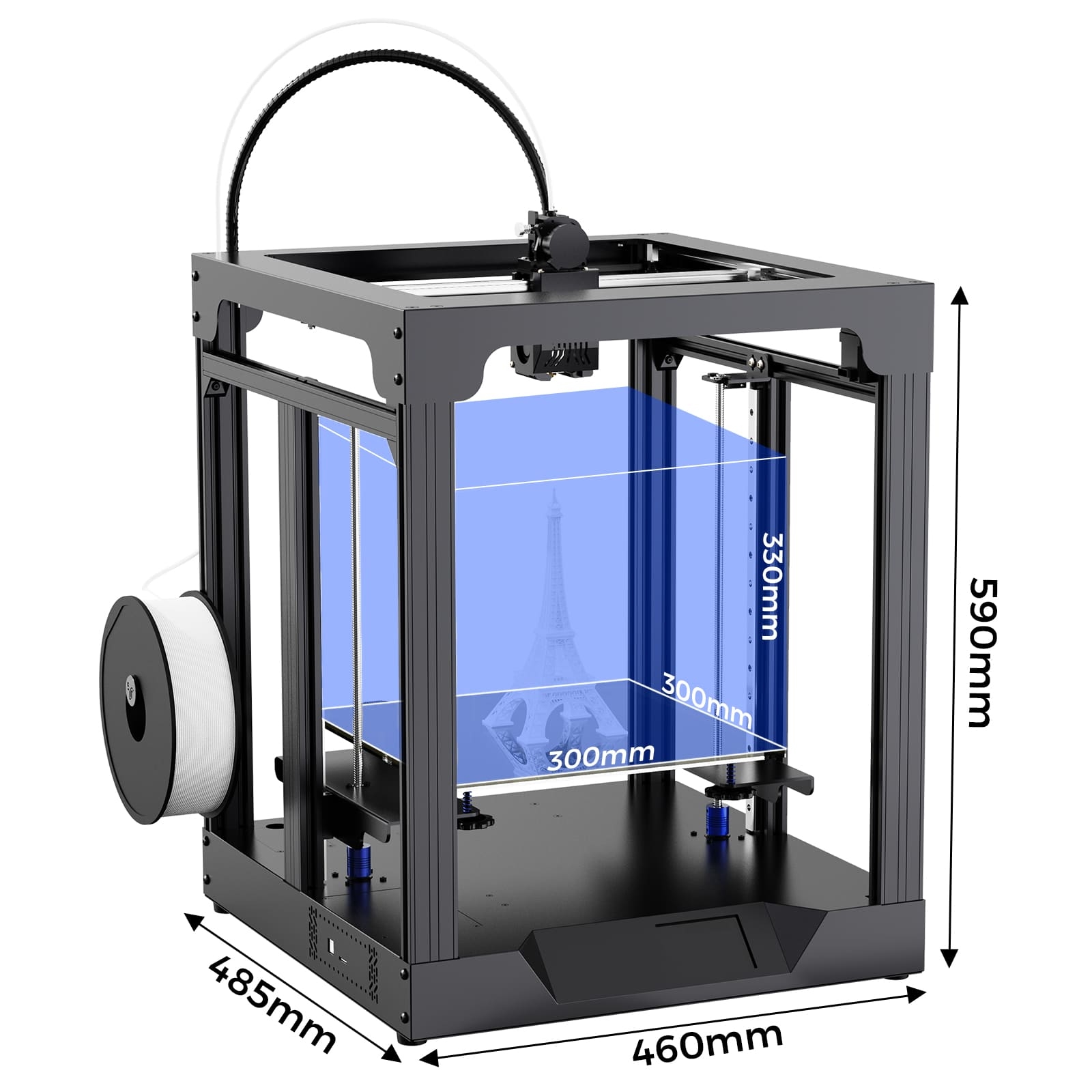

The SP-5V3 operates using a CoreXY motion system and a stable structural framework, complemented by the versatile Marlin mainboard. With a large print area of 300mm x 300mm x 330mm, it is an excellent choice for users who prefer large format and high-speed printing.

|

The SP-5V3 can print 3D models in both STL and STEP formats. Prior to printing, it is necessary to preprocess the file models using slicing software.

Taking Prusa as an example, the slicing software will slice the STL file into numerous layers, with each layer’s information automatically converted into code that the printer can read. This code instructs the printer on the movement paths and speeds of each axis during the printing process.

In addition, the slicing software can integrate various parameter settings into the generated code, such as the printing temperature of the filament, the temperature of the heated bed, the extrusion speed, and the movement speed of the printer. It can also generate supports for certain overhanging parts of the printed model.

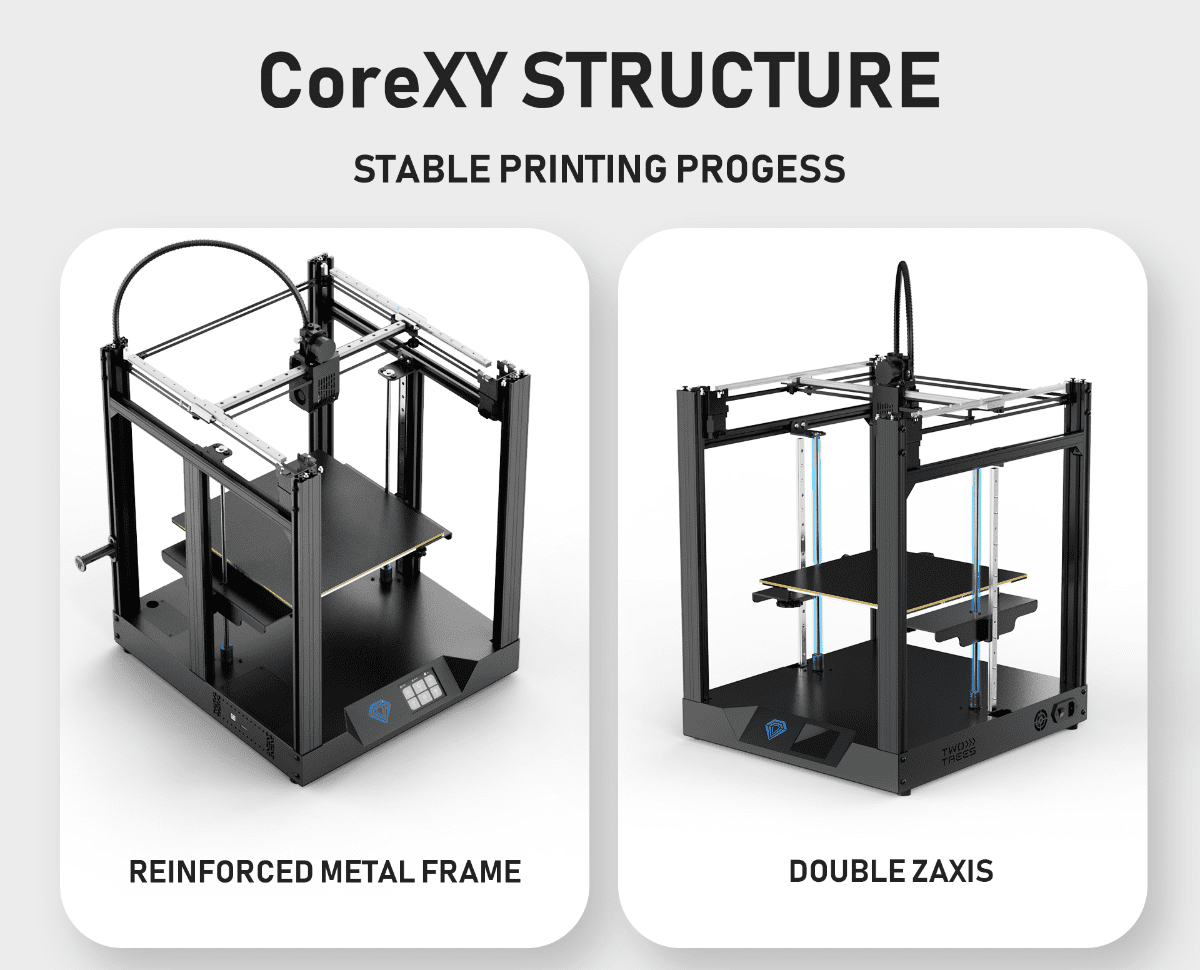

¶ CoreXY motion structure and Z-axis

The SP-5V3 utilizes a CoreXY motion structure for its XY movement. In a CoreXY configuration, both motors responsible for movement within the XY plane are fixed, reducing the weight of moving components and consequently lowering inertia. This design allows for higher acceleration under the same driving force, resulting in more agile motion. The advantage of this structure lies in its ability to provide greater stability, higher precision, and faster speeds during the printing process.

For the Z-axis, the SP-5V3 employs dual lead screws and dual rails, ensuring robust and precise vertical movement.

|

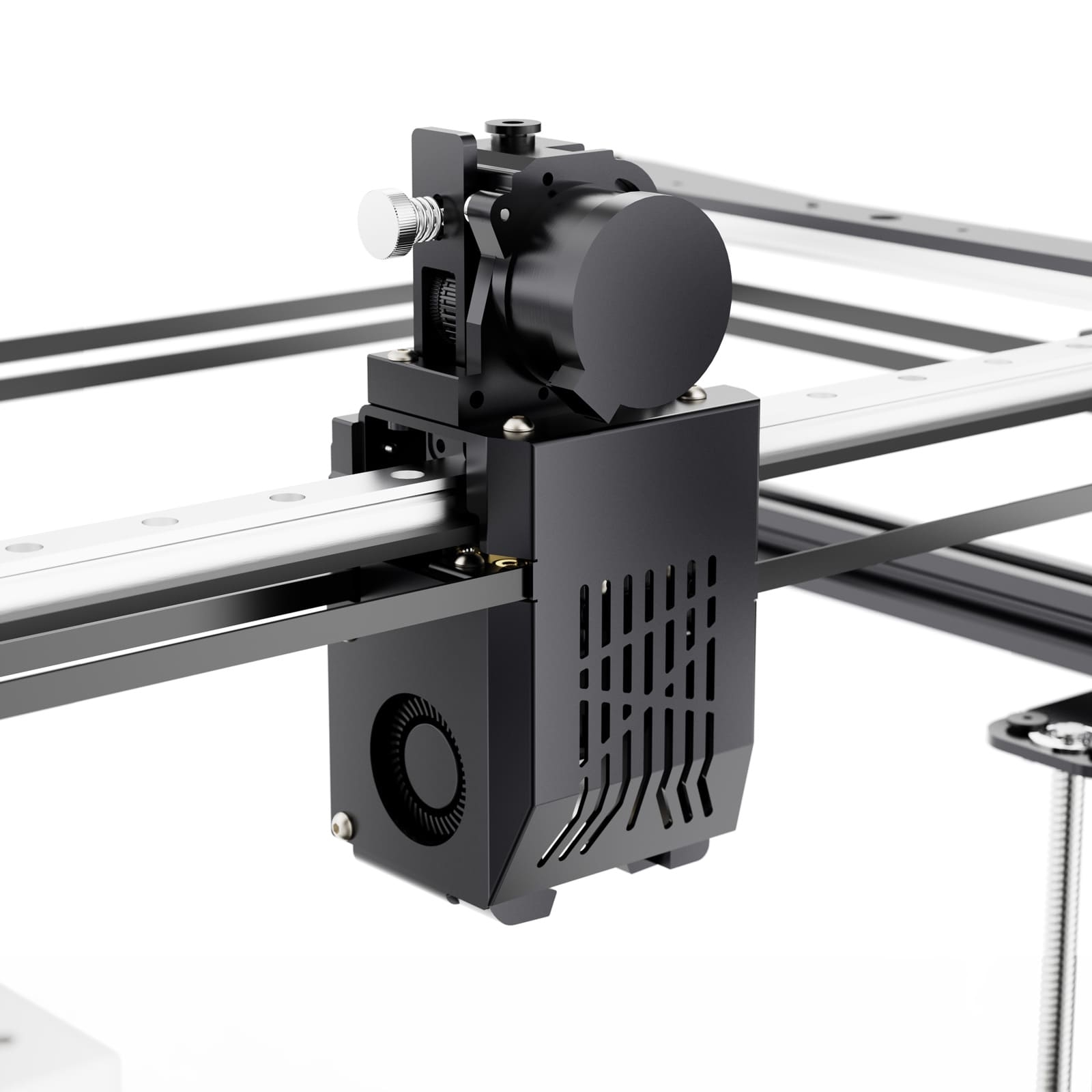

¶ Extruder

The SP-5V3 utilizes a short-range extrusion system, as opposed to traditional extruders which require longer filament feed paths with higher resistance. This necessitates stepper motors responsible for extrusion to possess greater torque. The filament and PTFE tube also exhibit some elasticity, and pneumatic fittings typically have a certain degree of movement allowance. Consequently, this setup requires larger retractions distances and speeds. Thus, the advantages of short-range extrusion lie in its precision, stability, and suitability for high-speed printing.

|

¶ Hotbed

The heated bed is used to heat the surface of the printing panel, aiding in better adhesion of the first layer to the printing surface. With a large printing platform size of 300mmx300mm, users can experience the joy of printing large models to a greater extent.

|

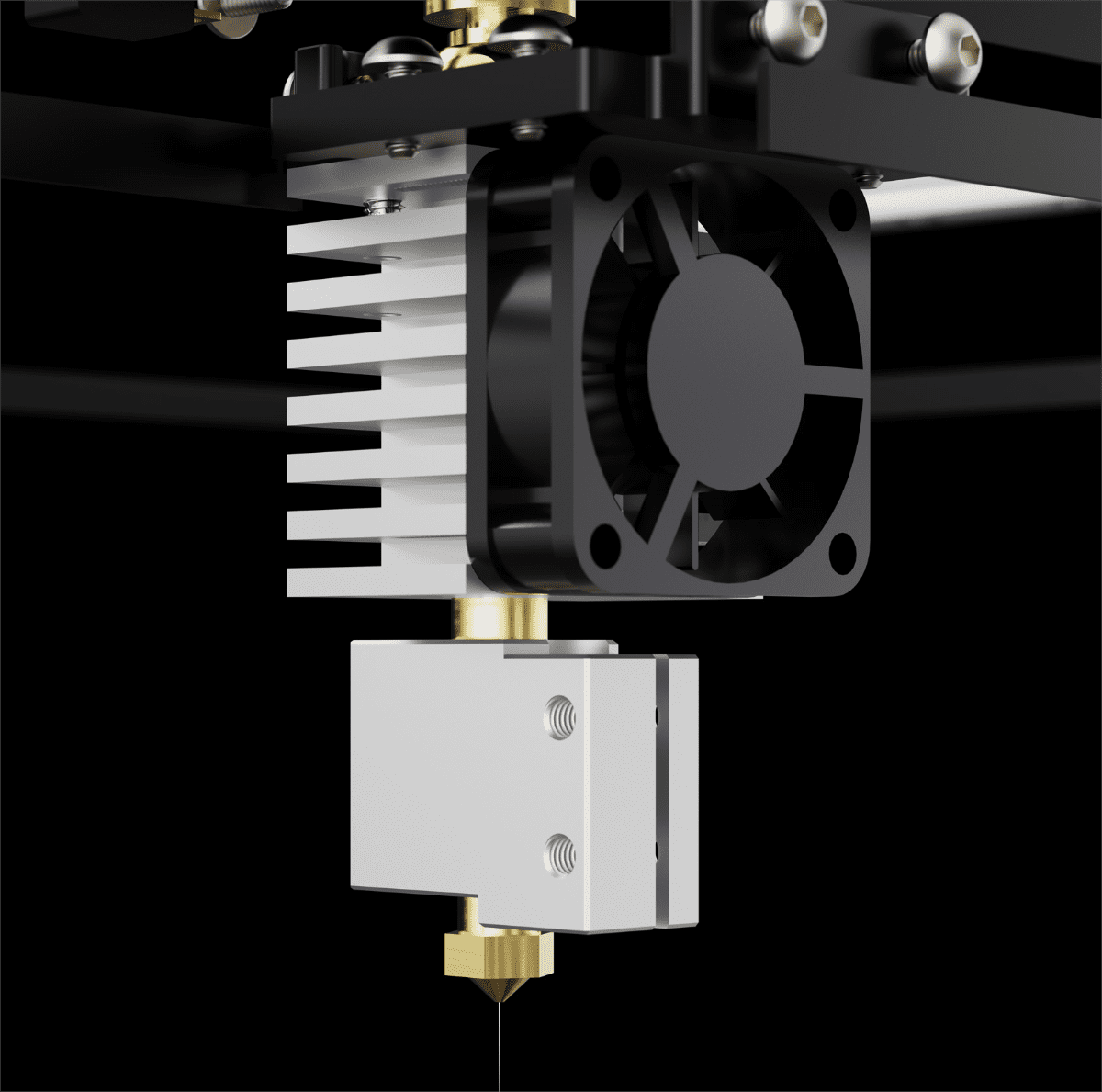

¶ Hotend

The hotend consists of a heatsink, fan, and nozzle, responsible for heating and cooling the material.

|