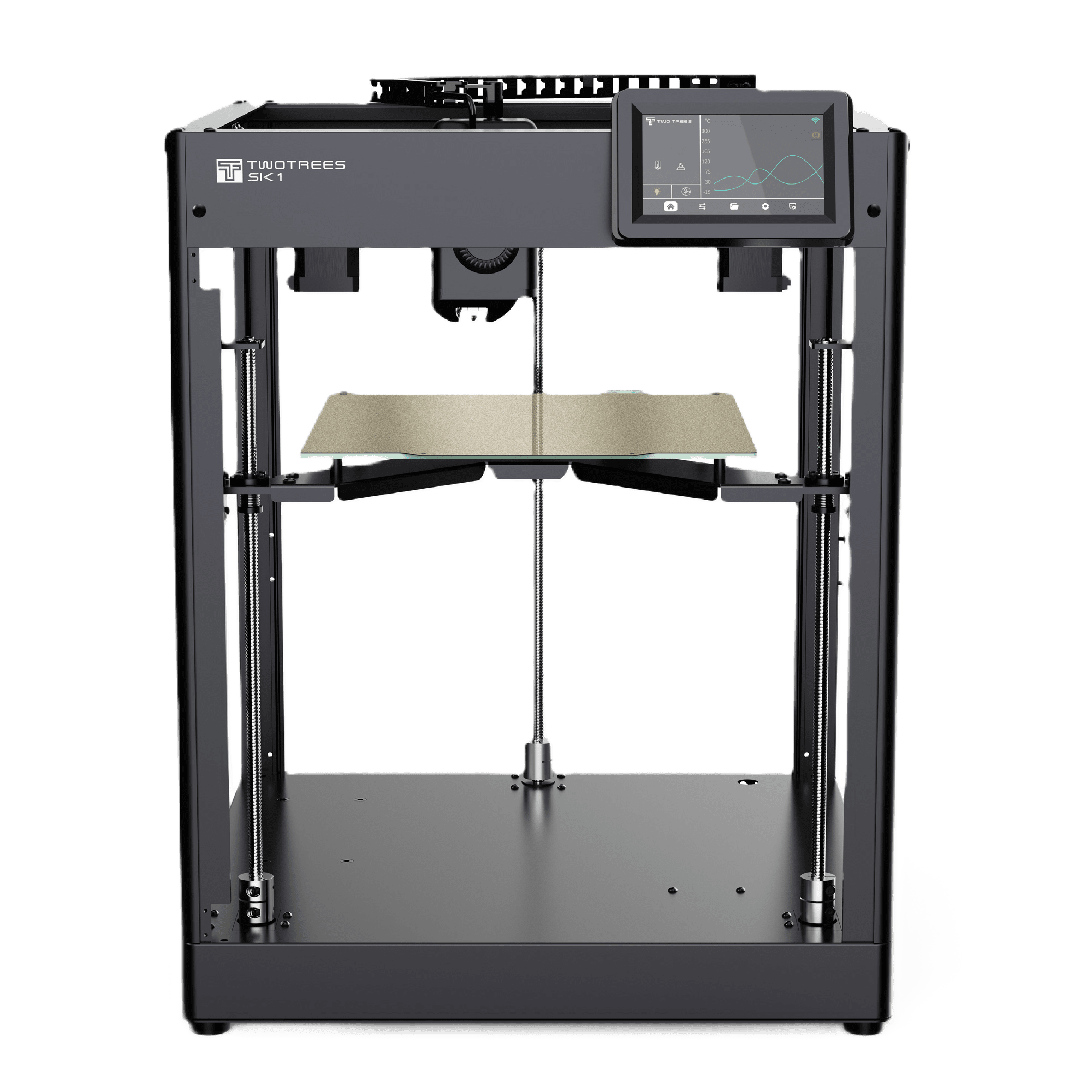

¶ Introduction to SK1 Main Components

¶ How SK1 Works?

SK1 utilizes advanced motion systems and a stable structural framework, coupled with high-precision sensors and a high-performance Klipper mainboard. We are continuously striving to innovate and improve, ensuring that all 3D printing enthusiasts can truly experience the joy brought by technology.

|

SK1 can print 3D models in both STL and STEP formats. Prior to printing, it is necessary to preprocess the model files using slicing software. Taking Prusa as an example, the slicing software will segment the STL file into numerous layers, with each layer's information automatically converted into code that the printer can read. This code is used to indicate the movement paths and speeds of various axes during the printing process.

Furthermore, the slicing software can integrate various parameter settings into the generated code. These settings include printing temperature for the filament, temperature of the heated bed, extrusion speed, and movement speed of the printer. Additionally, the slicing software can generate supports for certain overhanging parts of the printed model.

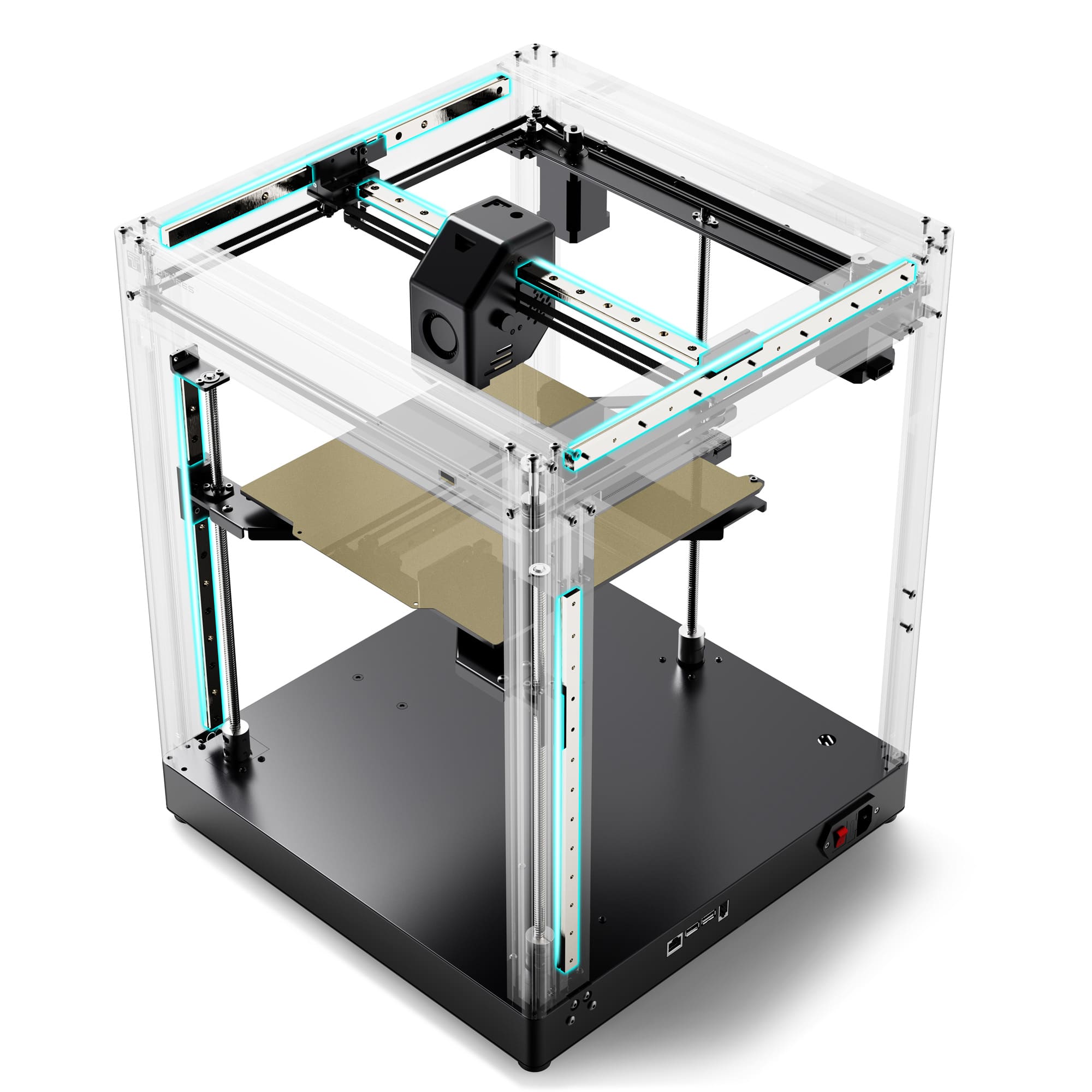

¶ CoreXY Motion Structure

The XY motion system of the SK1 employs the CoreXY motion structure. In the CoreXY configuration, both motors responsible for motion within the XY plane are stationary. This reduces the weight of moving components, consequently lowering their inertia. With the same driving force, this setup allows for higher acceleration, resulting in more agile motion. The advantage of this structure lies in its ability to provide greater stability, higher precision, and faster printing speeds during the printing process.

|

¶ Z-Axis

The SK1 utilizes three independent motors for the Z-axis, combined with two linear guides. This configuration enables more precise automatic bed leveling and ensures greater accuracy in printing layer heights.

|

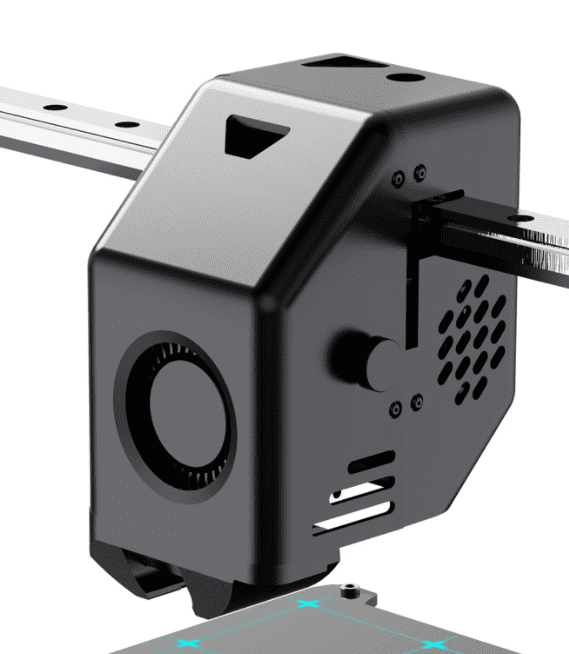

¶ Extruder

The SK1 employs a direct extruder to enhance print quality, resulting in higher precision. This setup particularly shines when printing with softer filament materials, further improving print quality. Additionally, when paired with a turbofan, it accelerates model solidification, ensuring faster curing times.

|

¶ Hotend

The SK1 printer features an integrated design for its hotend, where the nozzle and heat sink are combined, connected to the heat sink via thin metal tubing to achieve excellent performance. With this integrated design, the hotend heats up much faster than conventional ones, minimizing the issue of difficult-to-unclog blockages. Additionally, it greatly enhances the portability of replacing hotend components.

|

¶ Heated Bed

The heated bed is used to heat the surface of the print bed, boasting rapid heating speeds to assist in better adhesion of the first layer to the print surface. Additionally, with a print size of 256mmx256mm, the SK1 provides users with the enjoyment of printing larger models.

|

¶ Touchscreen

The SK1 features a 4.3-inch IPS full-color capacitive touchscreen. Capacitive touchscreen technology operates by utilizing the body's electrical conductivity for interaction. The touchscreen offers higher touch accuracy compared to traditional screens.

|